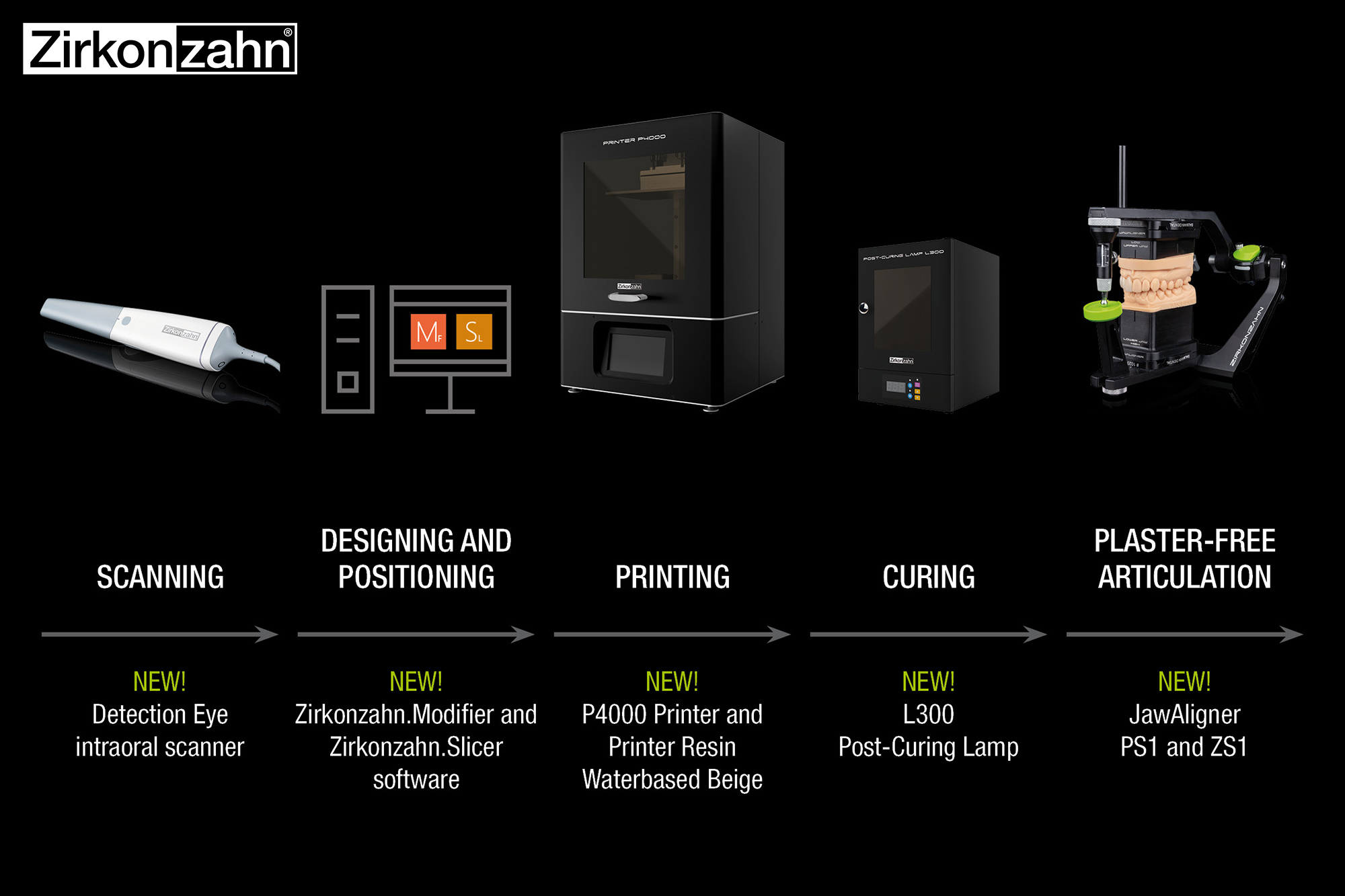

Zirkonzahn’s newest release is an easy to use add-on package for digital workflow with a seamless and well-calibrated print process.

With Zirkonzahn’s new Detection Eye intraoral scanner, the patient’s jaw can be easily digitised in less than 60 seconds.

The scanner is easy to use and the choice of two different tips (standard and small) makes the impression-taking more comfortable and patient-friendly.

The scanner has been designed to be lightweight, compact and ergonomic, and the scanning areas do not need to be pre-treated with powder, which simplifies the acquisition process.

Once the data has been captured, it can be easily and quickly loaded into the Model Maker software module for the design of a model.

The created model is then transferred to the new Zirkonzahn Slicer software, where it is placed on the printing platform and, if needed, special supports can be generated.

A seamless process

The software is conceived for the dental workflow and is supplied with pre-configured settings for a seamless and well-calibrated print process.

The 3D print data generated can be transferred to Zirkonzahn’s P4000 Printer either via USB, LAN or wifi, and the large print volume (L x W x H: 20 x 12.5 x 20 cm) permits the simultaneous production of, for instance, up to 21 Geller models or 15 dental arches, depending on their structure and dimensions.

The P4000 3D printing system works ideally in combination with the Printer Resin Waterbased Beige by Zirkonzahn. This resin is particularly suitable for the production of dental models and shows low shrinkage values, producing highly stable and reproducible printed objects.

The model can be cleaned in an ultrasonic bath and then cured in the L300 Post-Curing Lamp.

Subsequently, it can be positioned into the PS1 articulator or ZS1 Mini-Arti without the use of plaster thanks to the new Jaw Aligner PS1 or ZS1 (magnetic spacer plates), in order to check the patient’s jaw movements.

For more information visit www.zirkonzahn.com