Zirkonzahn discusses its range of implant abutments and the benefits that come along with them – including up to 30 years’ warranty.

As one of the world’s largest manufacturers, we use a high-quality medical titanium alloy (Ti-6Al-4V ELI according to ASTM F136 and ISO 5832-3) for the production of our implant prosthetic components. We also meet the strictest quality criteria (ISO 13485 MDSAP; Medical Device Directive 93/42/EEC; EU Regulation 2017/745 on medical devices).

All components are conceived and manufactured at our production sites in South Tyrol, Italy. We believe in what we do and we assume the responsibility for our products. In addition to the legally prescribed warranty obligation, there is up to 30 years’ warranty on all Zirkonzahn implant abutments used (titanium bases, Multi Unit Abutments, Multi Unit Abutments Angled, Raw-Abutments as well as the corresponding screws).

Within the current Zirkonzahn warranty regulation, we explicitly include also implants from other manufacturers used with Zirkonzahn implant abutments. Have a look at our renewed range of components at www.zirkonzahn.com and check if they are compatible with your implant system!

Zirkonzahn implant prosthetic components

For more than 140 implant systems and produced entirely in South Tyrol (Italy), Zirkonzahn Portfolio consists of a great range of products. These include regular titanium bases, Scanmarkers, White Scanmarkers, ScanAnalogs (our laboratory analogues used as scanmarkers), impression copings, laboratory analogues, Multi Unit Abutments, Raw-Abutments and healing caps.

The product line has been recently expanded with innovations such as new titanium bases, White Metal Scanmarkers, Zirkonzahn Titanium Posts, and Zirkonzahn LOC-Connectors. Zirkonzahn implant prosthetics components are 100% integrated into the workflow via corresponding libraries.

Exocad and 3Shape users may also download and implement Zirkonzahn components for free in their design software through a dedicated portal: the Zirkonzahn Library Download Center.

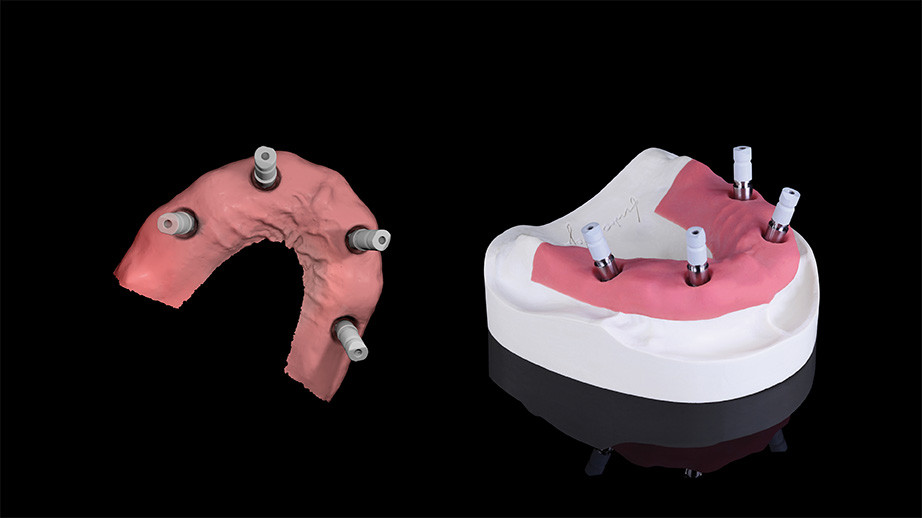

White Metal Scanmarkers

White Metal Scanmarkers are used to acquire implant position and orientation during introral or model scans. After appropriate sterilisation, they can be reused several times. White Metal Scanmarkers are particularly resistant, dimensionally stable, and visible on X-rays thanks to their plasma coating, which prevents light reflection during scanning (intra- and extra oral) improving scan quality. Suitable for any oral situation, our White Metal Scanmarkers are available in three different lengths: L10, L12 and L15. The White Metal Scanmarker L10 is the shortest and provides the intraoral scanner with a sufficient scanning area in case of limited space (e.g. in the molar region). The L15 length, on the other hand, was developed for implants located deeply and with a high transmucosal height, to guarantee a larger scanning area.

Reusable scanbodies to acquire the implant position and orientation during intraoral and model scans.

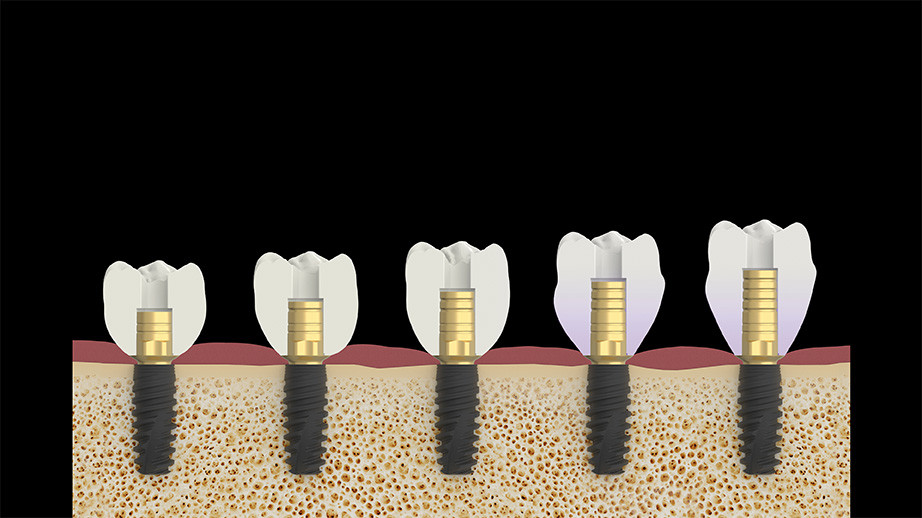

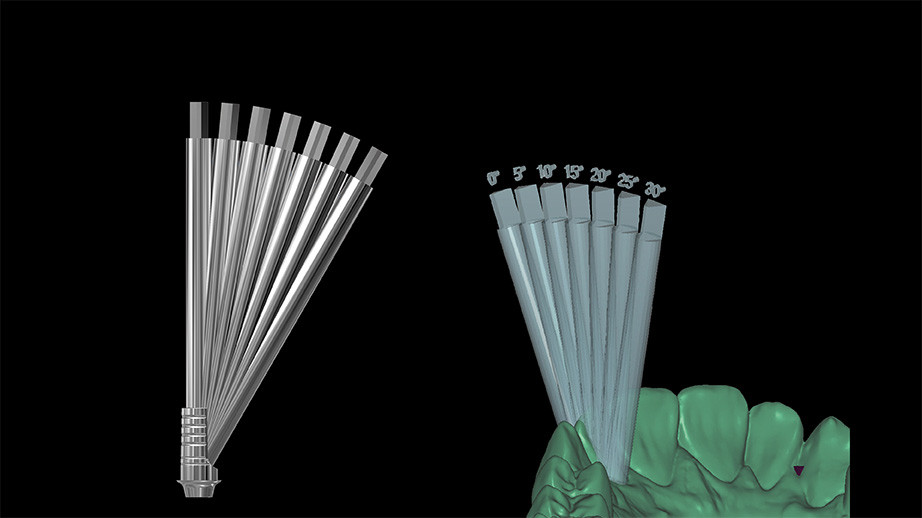

Titanium bases K85 and K80 Angled Screw Channel (ASC)

As with all Zirkonzahn implant prosthetic components, our titanium bases are manufactured with high-quality medical titanium alloy. Our portfolio of titanium bases recently expanded with the addition of new innovations for flexible and patient-specific restorative design:

- Titanium Bases K85 can be individually shortened for optimal adaptation to the respective tooth length and are available in different gingival heights. Equipped with a conical or parallel chimney, the Titanium Bases K85 are provided with or without an anti-rotation device as well as anti-rotation connection according to the restorative indication

- Titanium Bases K80 Angled Screw Channel (ASC) combine two advantages in one product. On the one hand, the adjustable chimney height ensures optimal stability and force distribution. On the other hand, the screw channel can be tilted up to 30° to compensate for non-optimal implant positions. Depending on the intended use, these bases are available with or without anti-rotation device as well as in different gingival heights.

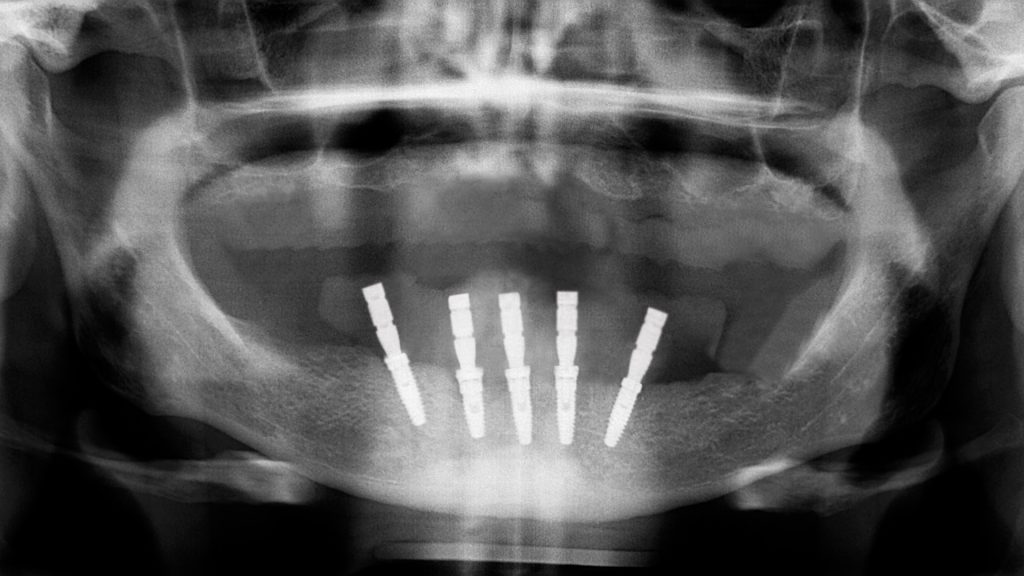

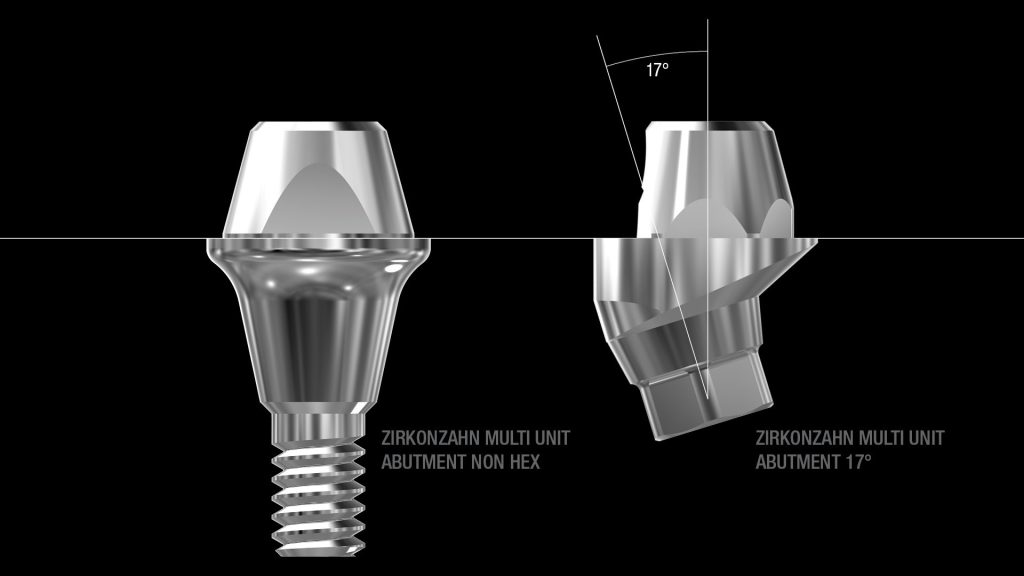

Multi Unit Abutments 17°

Multi Unit Abutments (MUA) are specially suited for multi-unit restorations. The connections to the secondary structure are unified so that the latter can be screwed directly – or with additional titanium bases – on different implants. Thanks to the standardised connection, also other components such as titanium bases, Scanmarkers, etc, are reduced to one connection to compensate for divergences. Multi Unit Abutments exist in two different versions: straight and angled.

- Straight MUAs without anti-rotation connection as well as anti-rotation device on the platform, are specially suited for multi-unit restorations and are designed in one piece to prevent bacterial entrance. Their application is extremely easy, because all types of implants have been adapted on a standard connection. In order to offer the best possible solutio foe each case, they are also available in five different gingival heights

- The new Multi Unit Abutments 17° are currently available with a 17° angle to compensate for any implant inclinations and with two different anti-rotation connections which allow intermediate positions. They can be used for single crowns and multi-unit restorations.

MUAs are incorporated to correct the insertion direction of structures retained by divergent implants. A variety of platforms is offered (hexagonal, square, triangular and octagonal): each geometry is available in two different typologies (1 and 2), effectively doubling the connection possibilities.

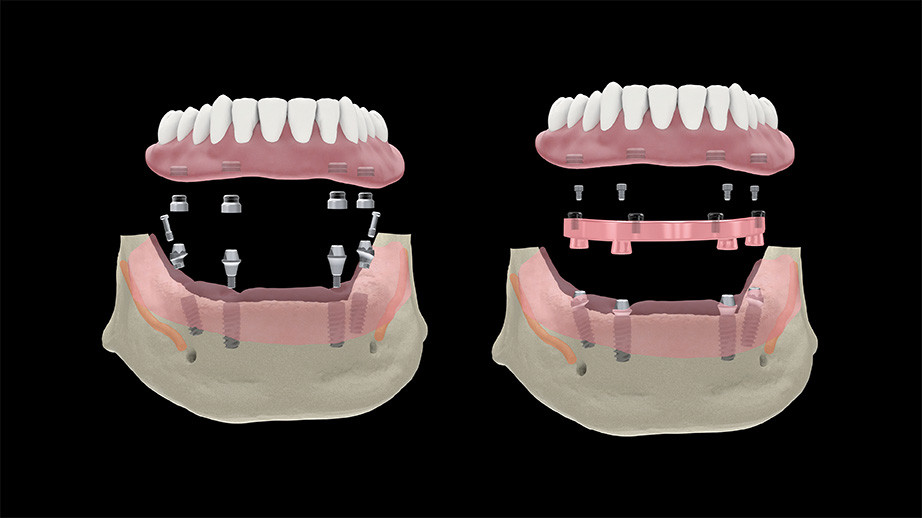

Zirkonzahn LOC-Connector

Zirkonzahn LOC-Connector is a snap attachment for implants and bars which is used to fix removable dental prostheses on the implants. The Zirkonzahn LOC-Connectors combine the advantages of removable and fixed prostheses, and their snap-on mechanism allows both patients and dentists to insert and remove the restoration easily. They can be used for bridges only and on Zirkonzahn Multi Unit Abutments, Multi Unit Abutments 17° and metal bars.

For more information, visit www.zirkonzahn.com.