Ralph Riquer demonstrates the many possibilities of 3D printing in everyday laboratory life and how it can support the entire work process.

With the introduction of 3D printers into everyday dental laboratory life, the question of additional possibilities and areas of application for this technology is becoming more and more common.

Modeling for IOS data (intraoralscan data) does not burden the 3D printer in many laboratories, resulting in free machine time to be used. The focus now falls on peripheral areas of dental production.

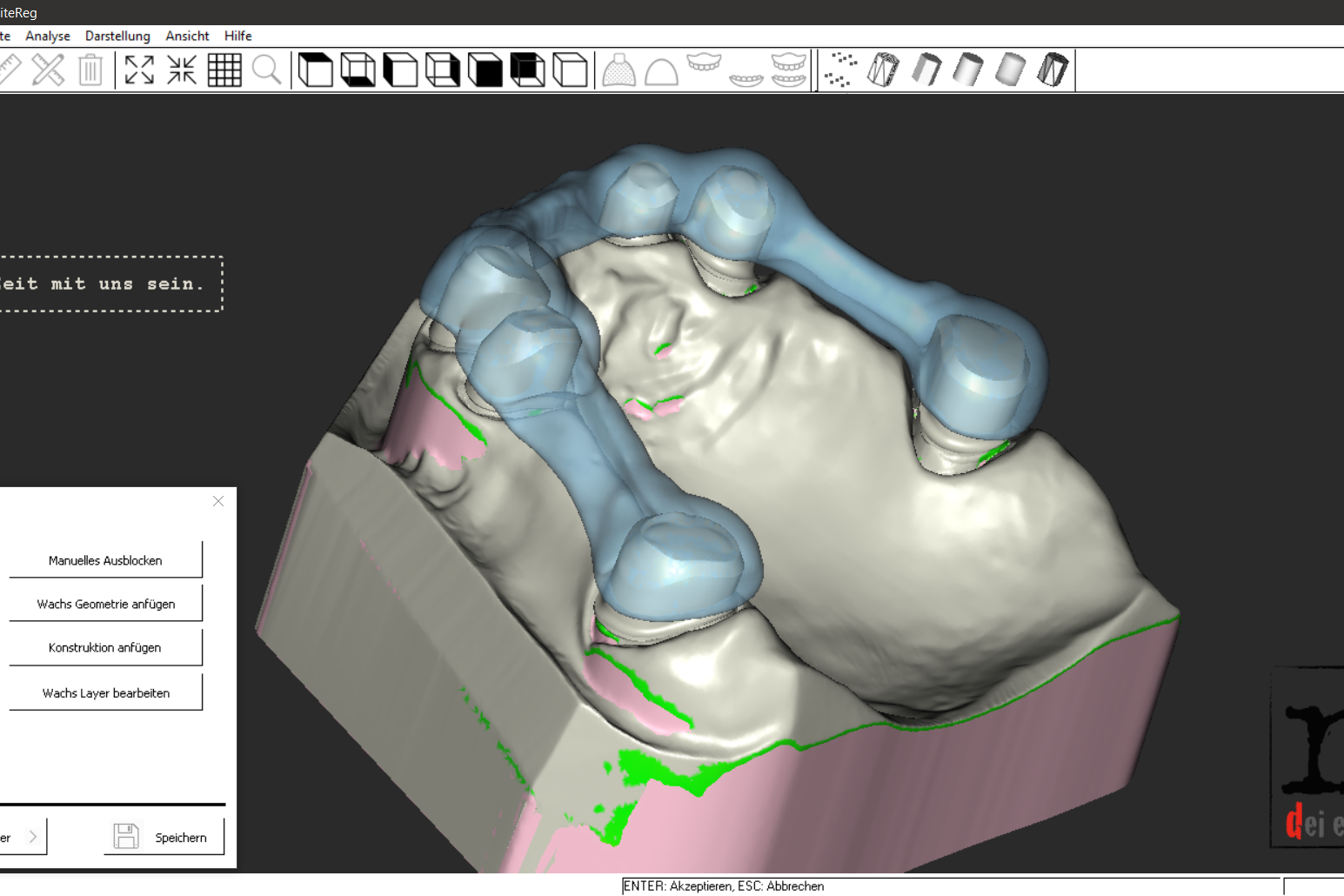

Auxiliary parts represent a not to be underestimated share of the total work (Figure 1). We often find these in preparatory process steps in function impression, bite registration, jaw relations, determination and backward planing.

Production

These auxiliary parts can be designed in a wide range of dental CAD software programs.

Since the software is often not specifically designed for these indications, some ‘detours’ have to be taken, or an expert knowledge in the application is required.

However, since the most cost-effective design of auxiliary parts does not justify an increased time expenditure in the CAD/CAM department, the use of corresponding ‘special’ software directly in the plastics department can be a useful addition.

Such stand-alone software solutions, such as Bite Reg or Easy Base, are specially adapted for use in the plastics department. Their handling is simple and the work- steps to follow logically correspond to the indications.

Use

The advantage of a special software solution is always its consistent adaptation to the indication area.

Without detours and adapted to the personnel employed, work steps in a workflow can be easily mapped. The possible auxiliary parts and the specially tuned software functions are described below using the Bite Reg software.

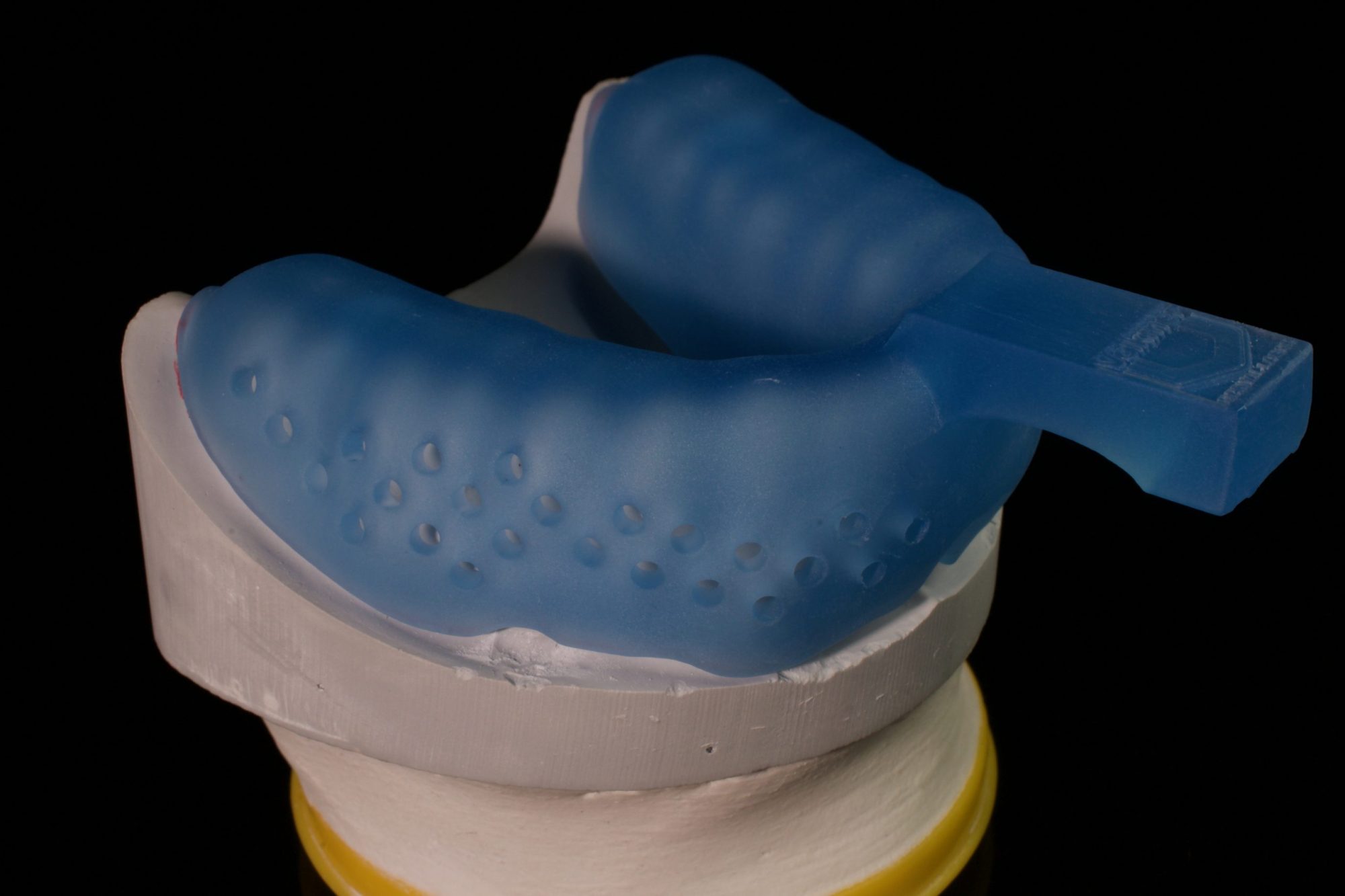

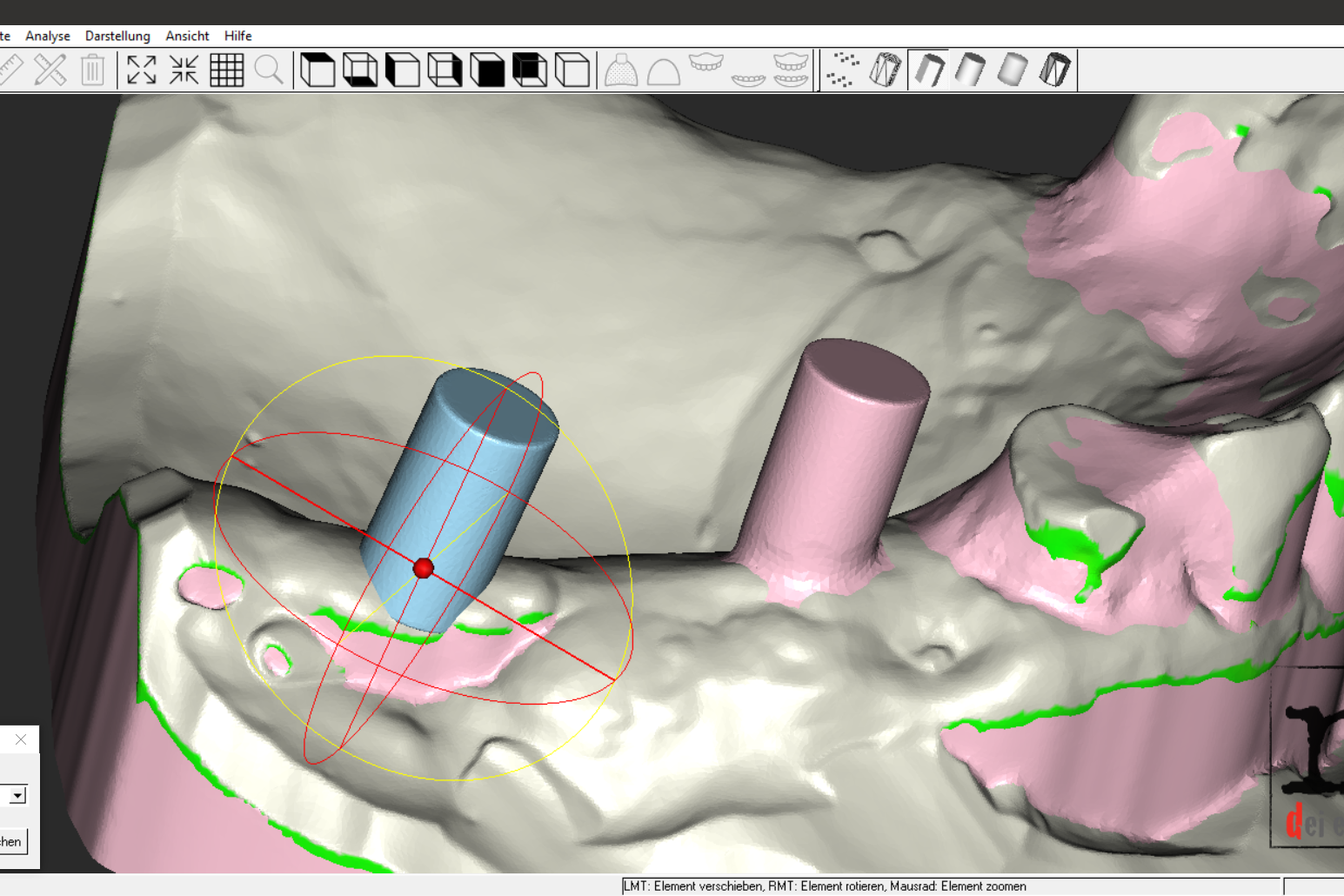

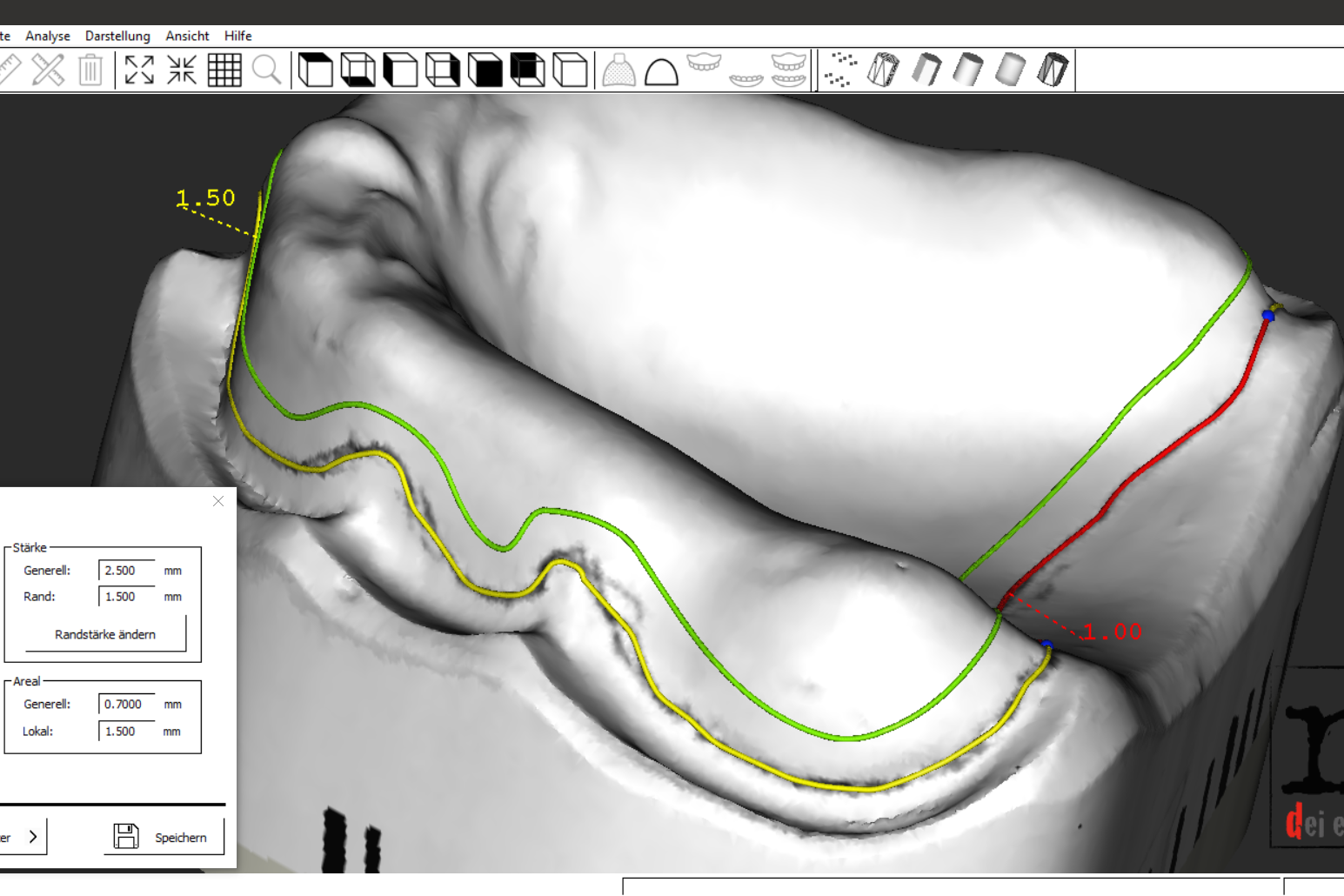

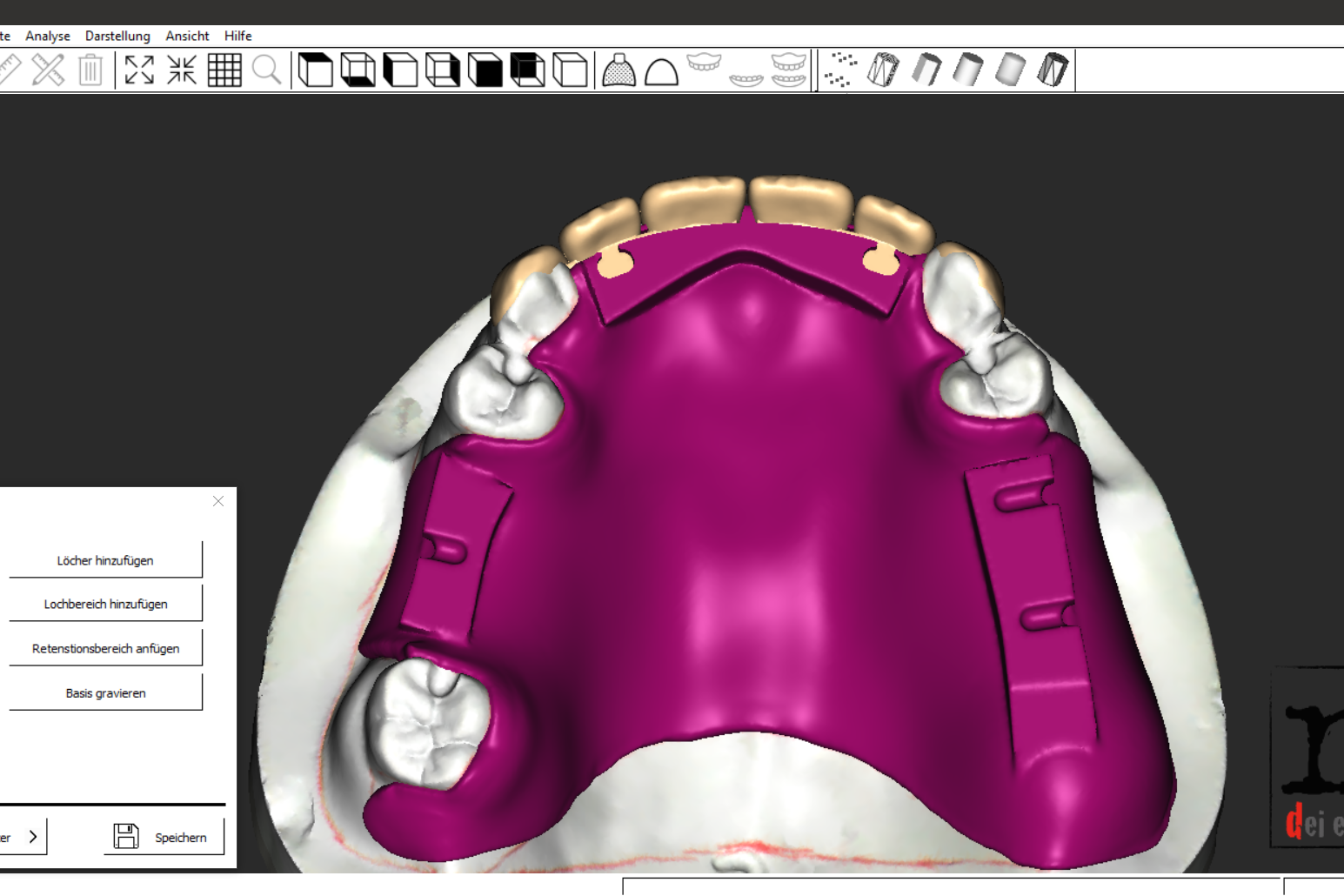

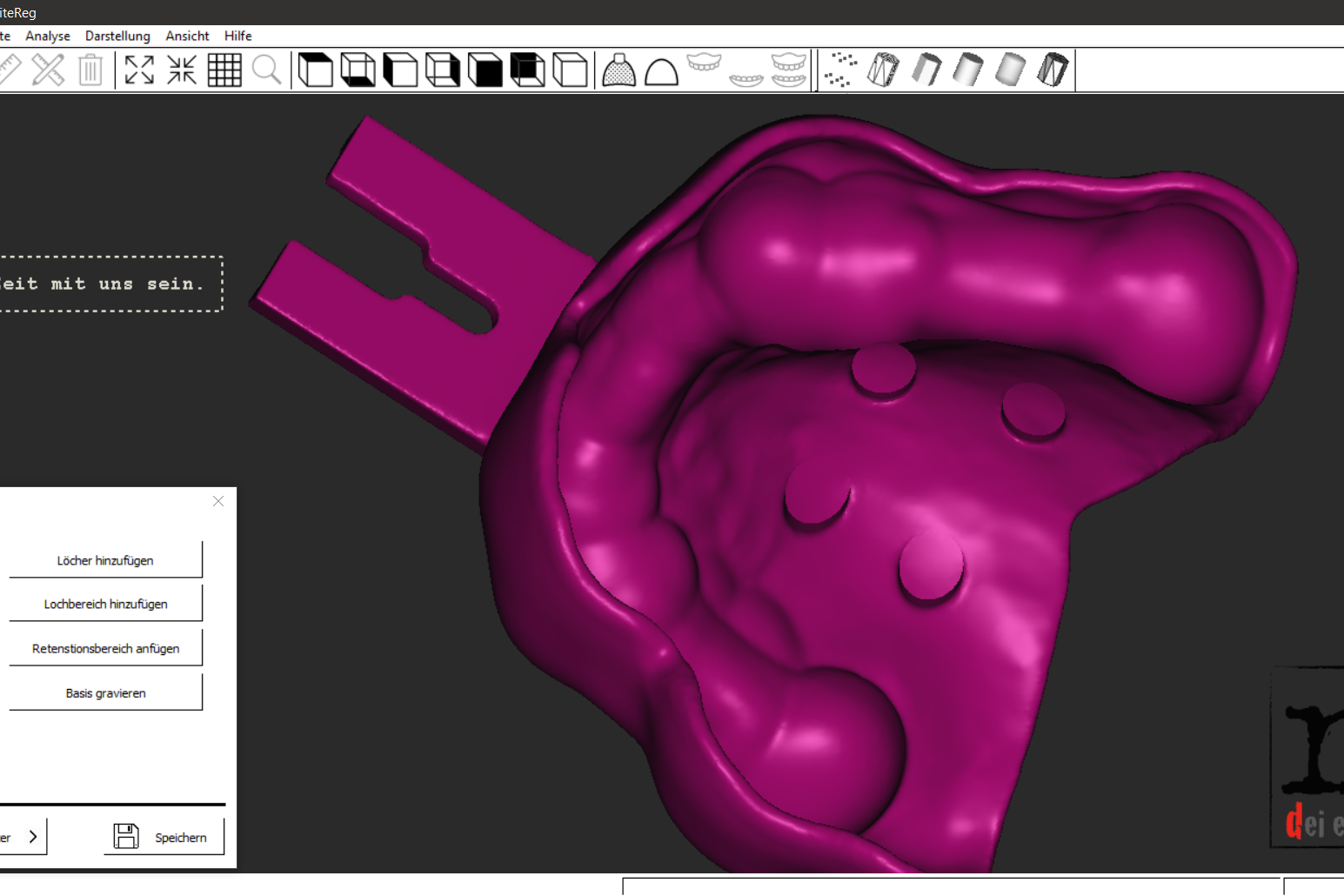

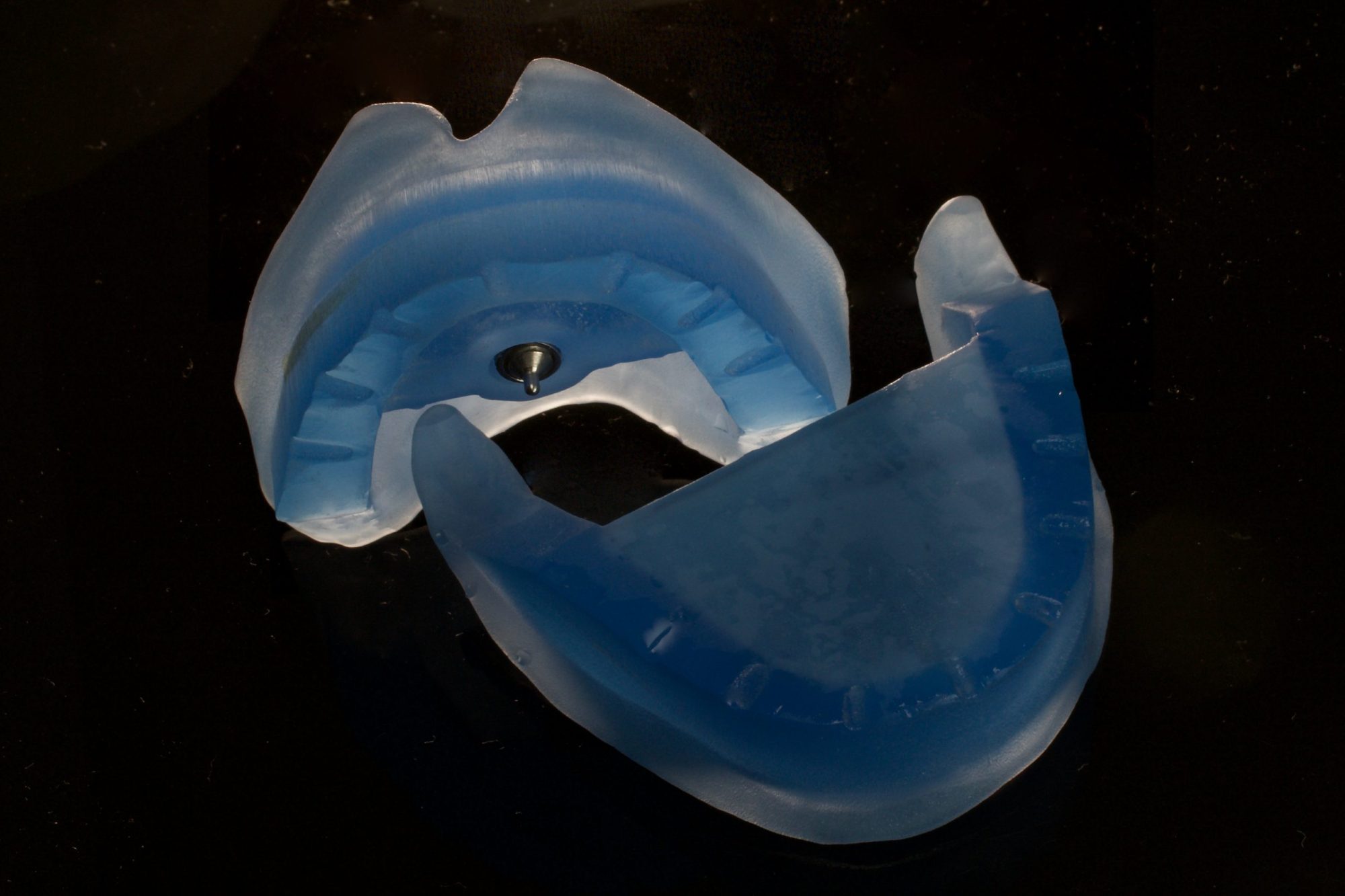

Digital tray (Figure 2):

In the case of PLY data, the marking of the tray limit is automatically recognised. Furthermore, tray handles are automatically aligned according to the occlusion plane and with the lower edge 20 mm away from the envelope fold.

- Different block areas can be defined

- The tray edge design is freely adjustable at each position

- Gaps and gingiva stops can be created variably

- Defined placeholder cylinders for impression posts with open and closed implant forming can be placed freely (Figure 3)

- The design of a compression edge is also easy (Figure 4).

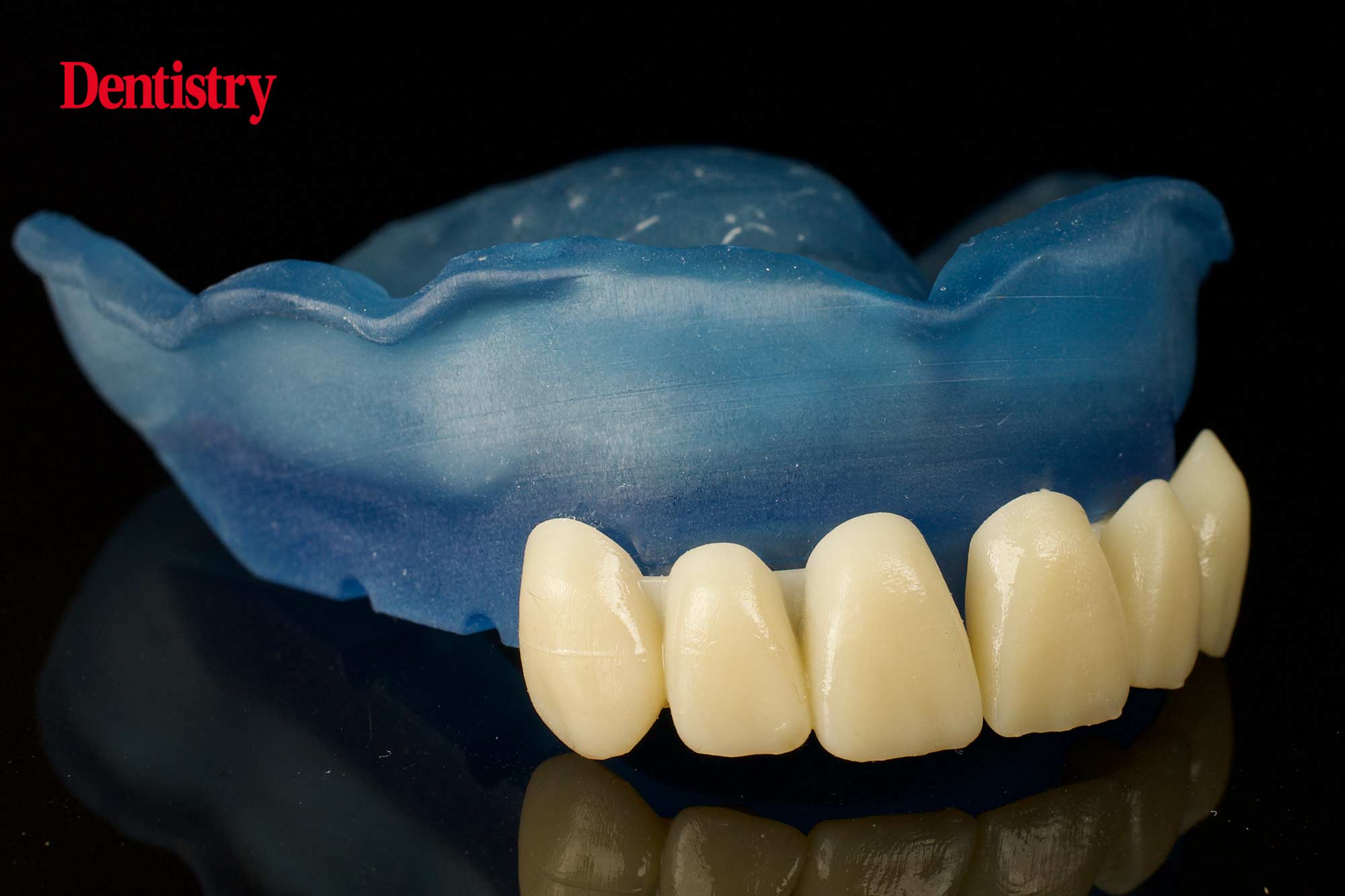

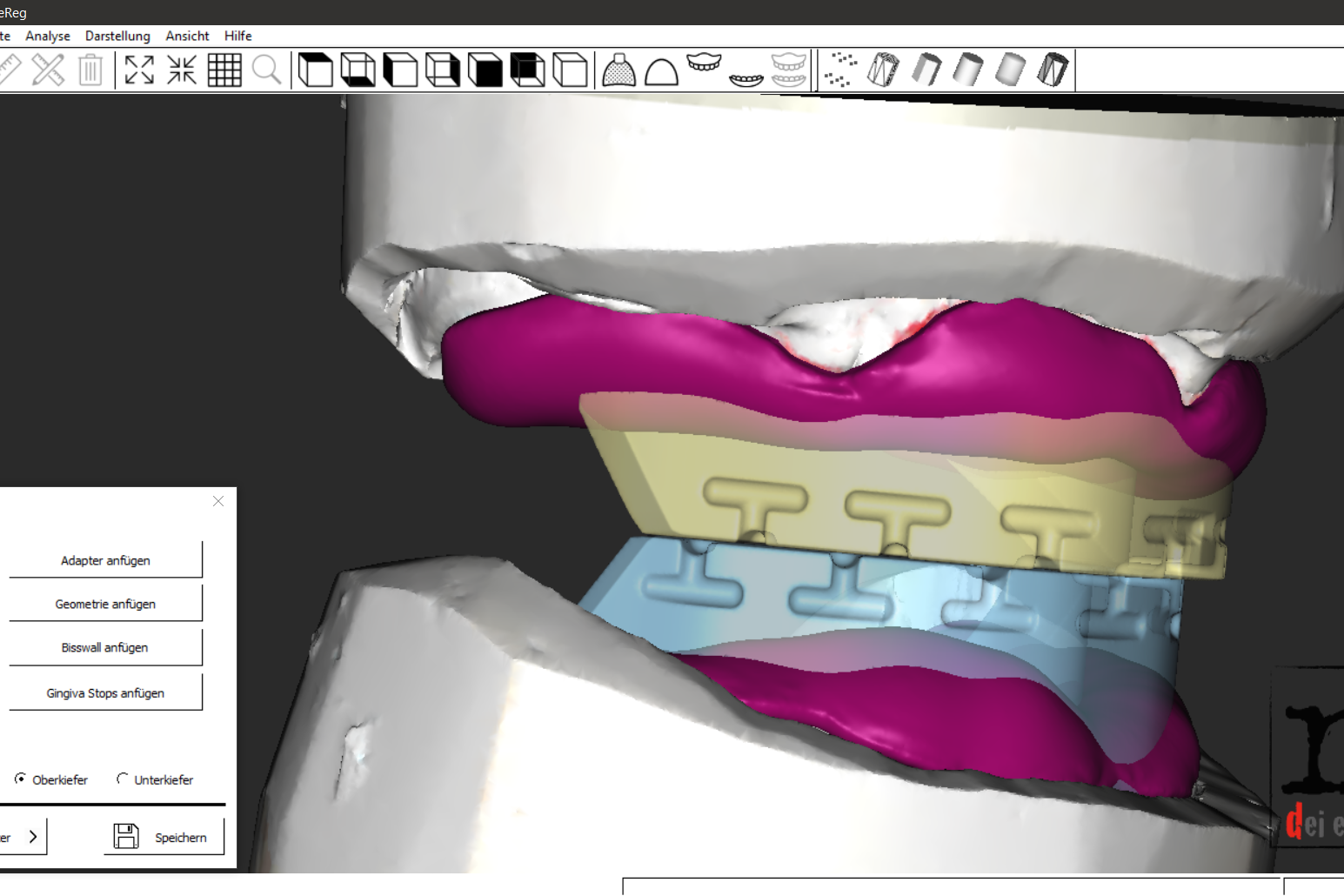

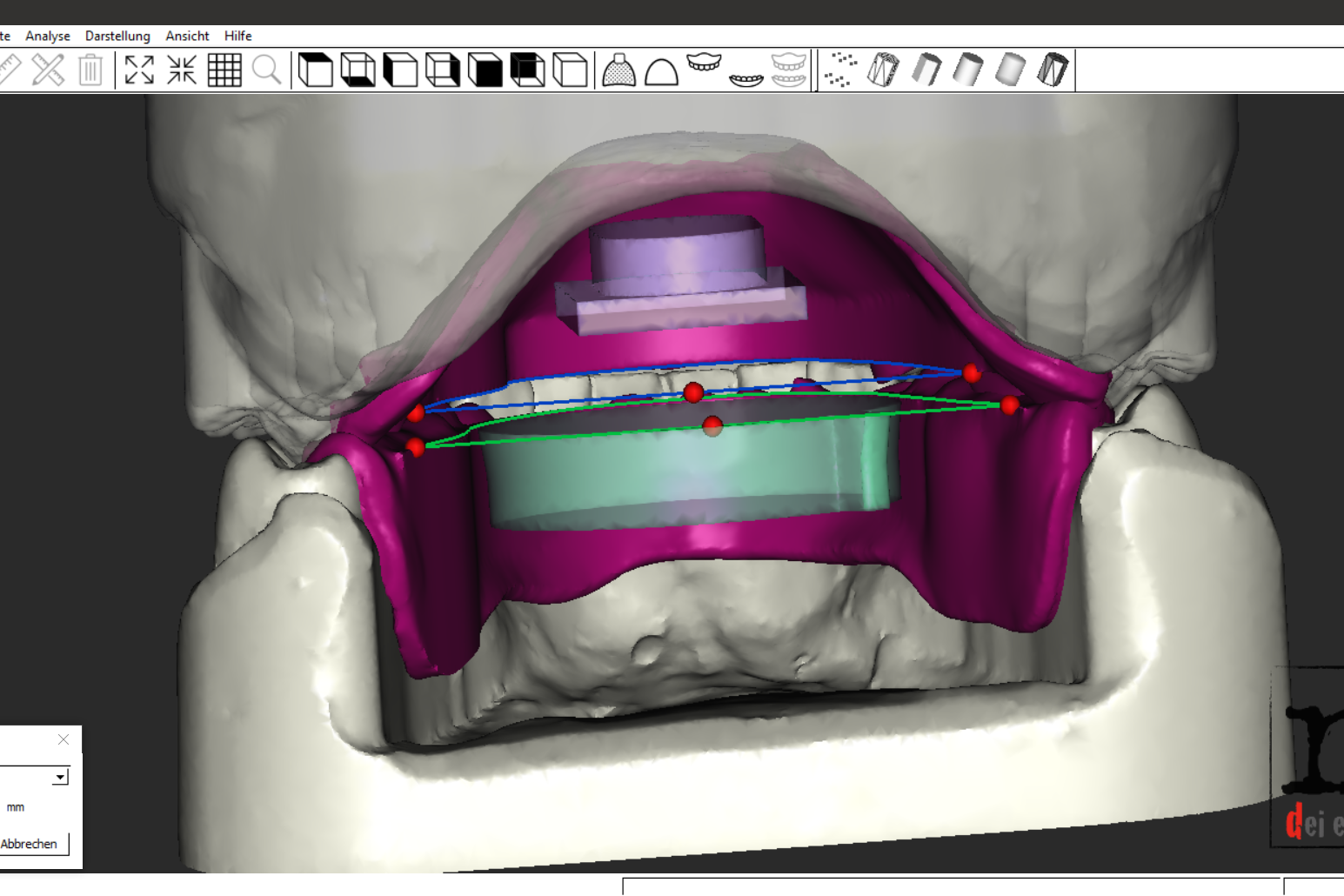

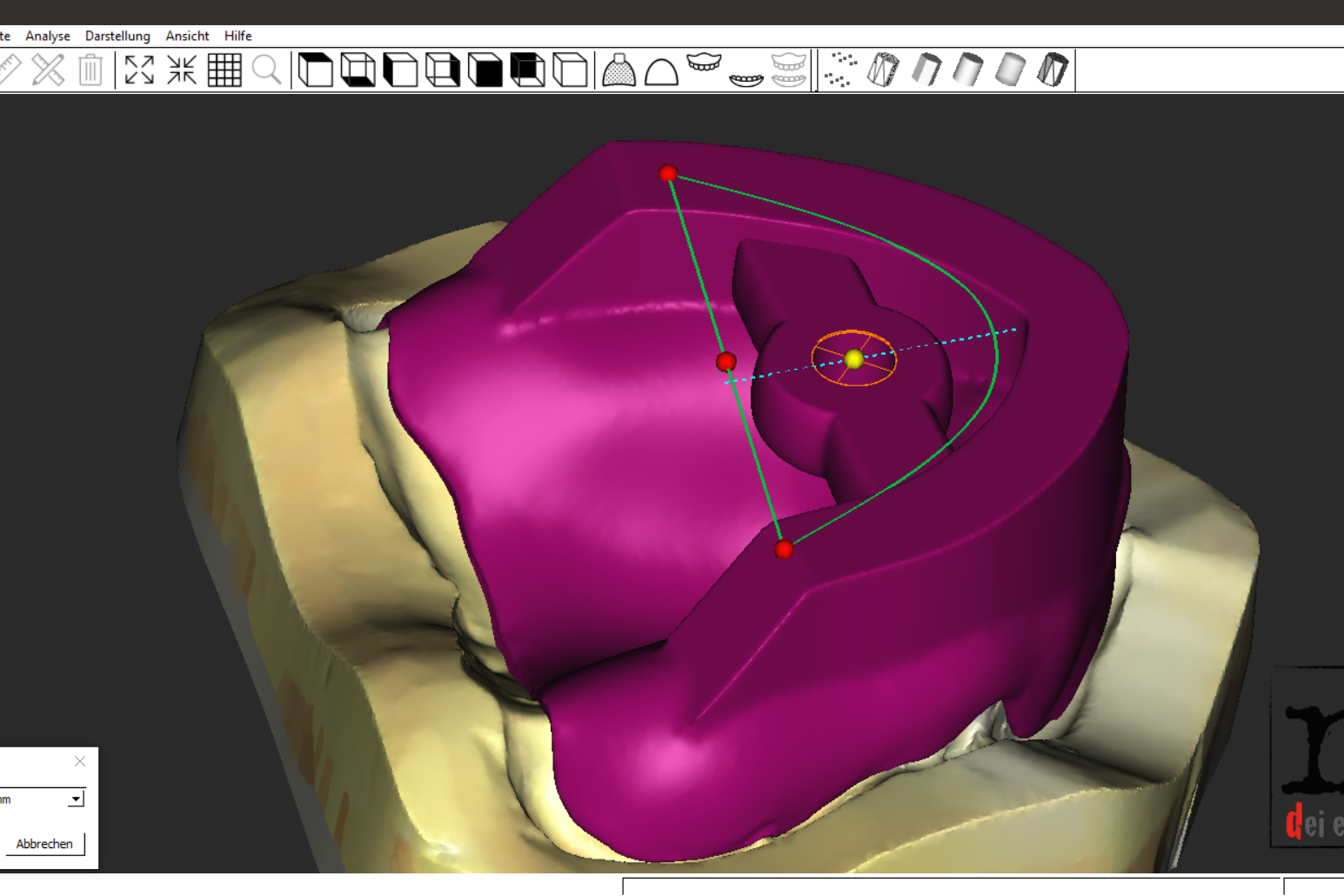

Bite registration (Figure 5):

- Figure 5 shows a simple blocking function of the palate and the sulcus area

- It is possible to integrate rows of teeth into the bite for a first aesthetic check, as seen in Figure 6

- This shows alignment of the bite ridge from upper to lower jaw with automatic locking system.

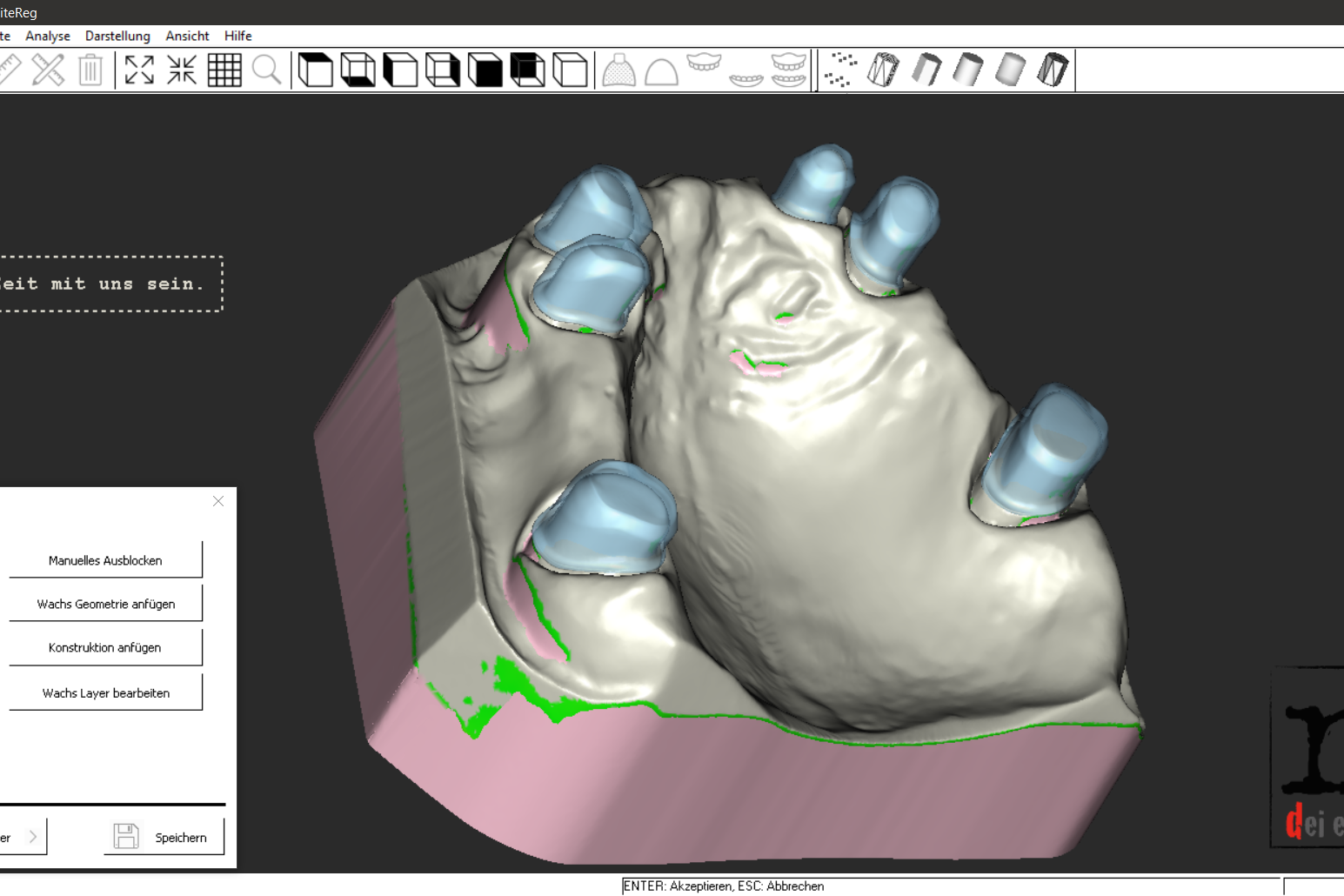

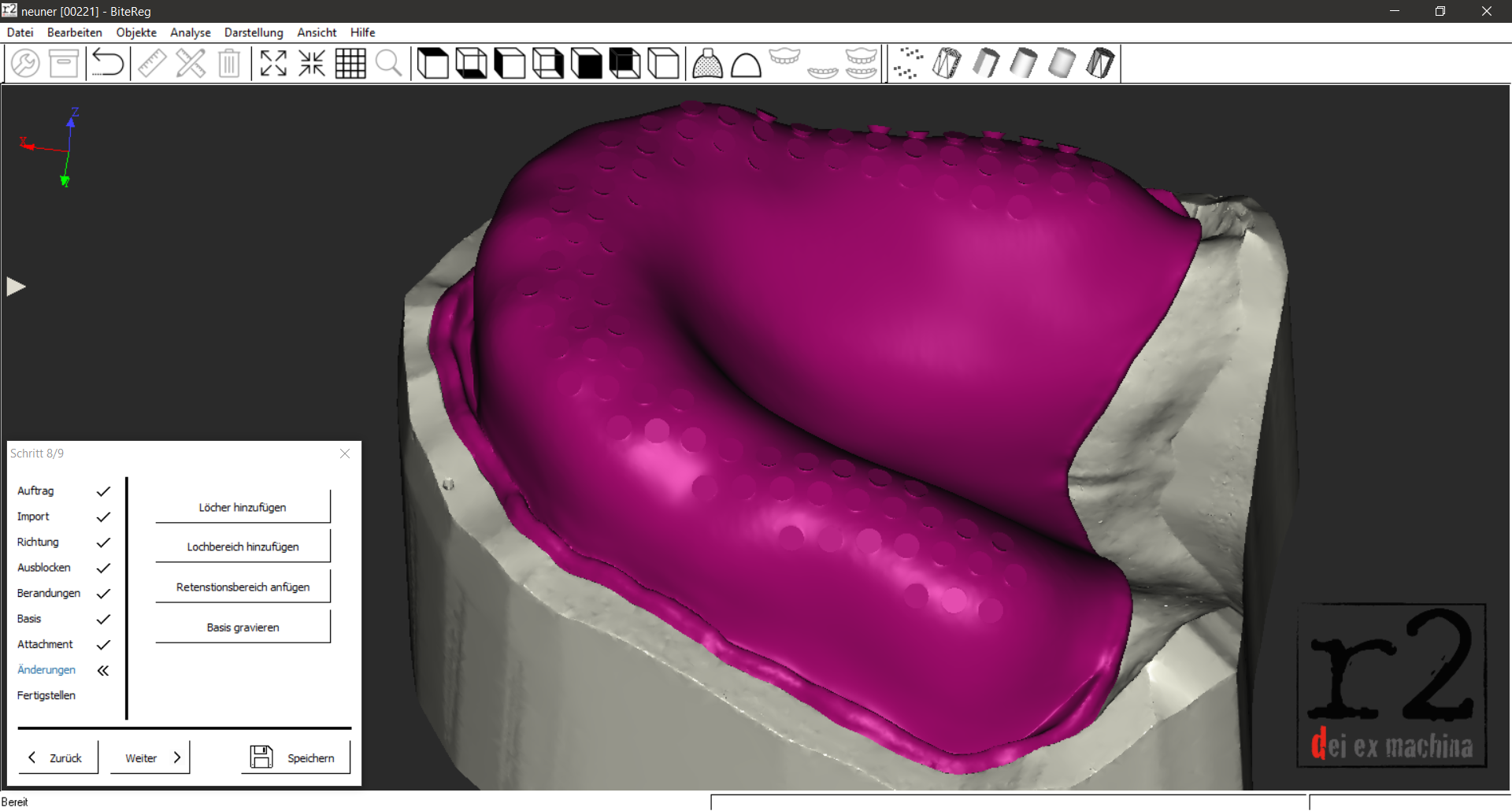

Set-up bases (Figure 8):

- Complete transfer of the valve edge

- Hollowing of individually identifiable areas, e.B. papilla incisiva and insertion of etchings

- Free creation of retension fields for better mechanical connection to the wax walls.

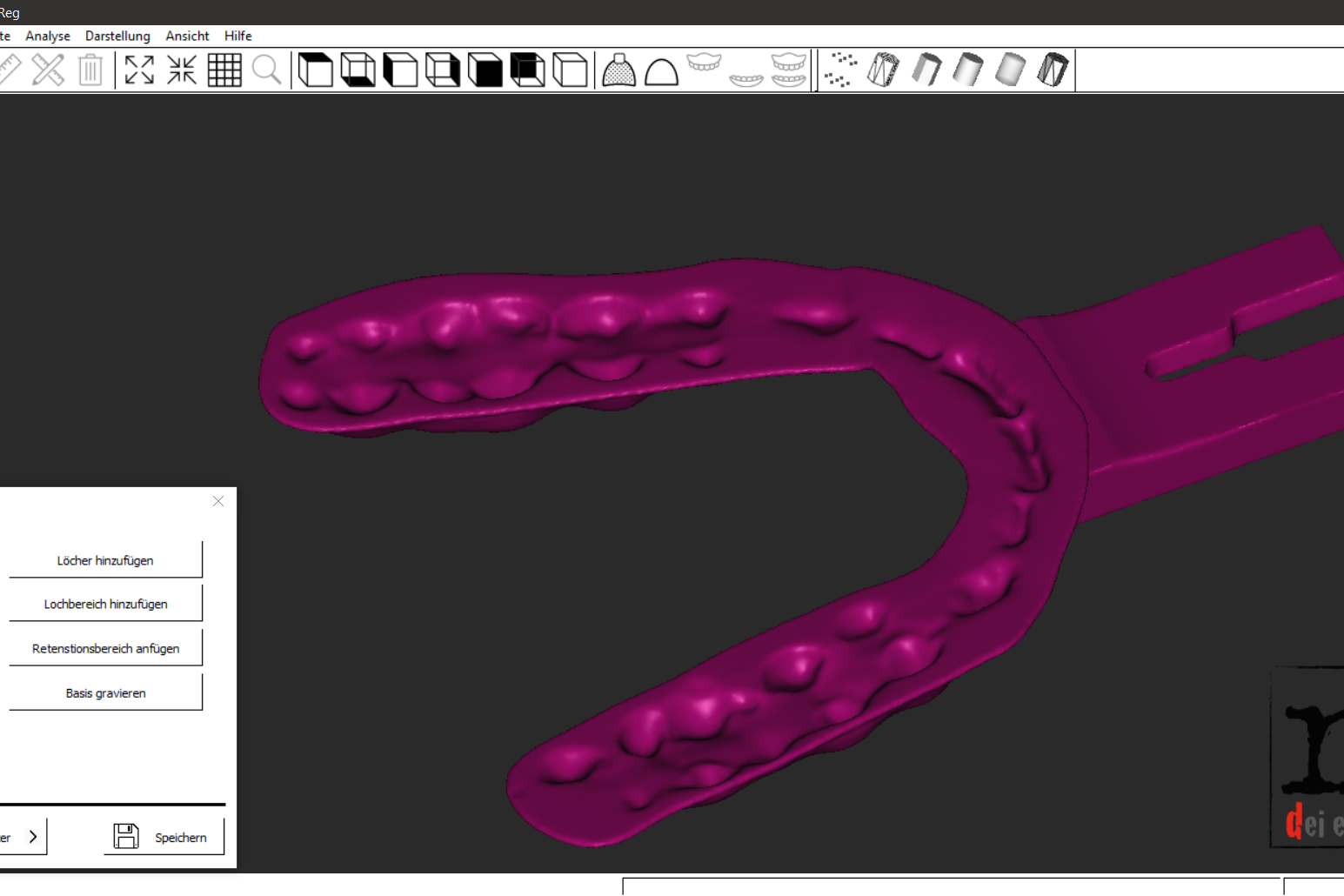

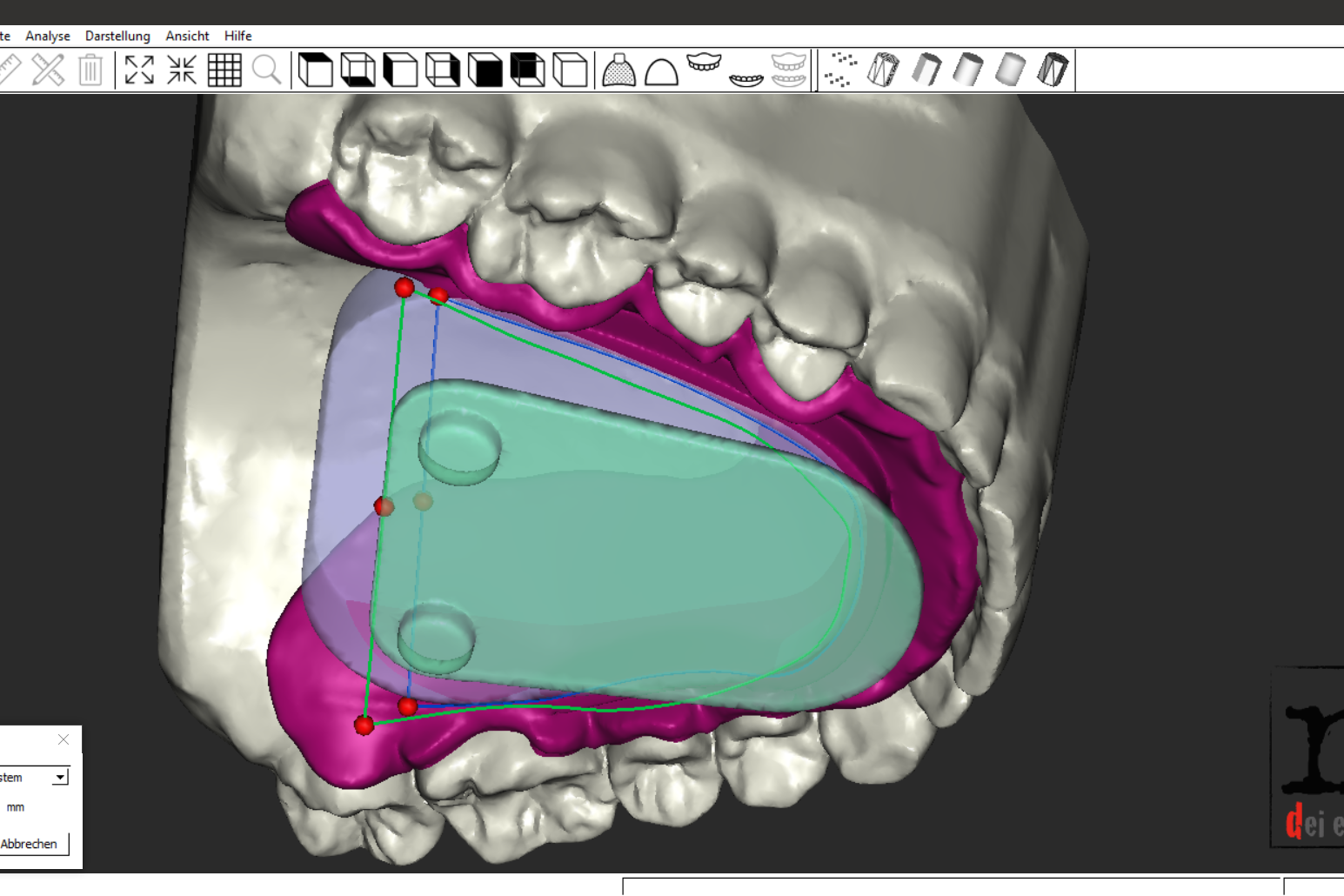

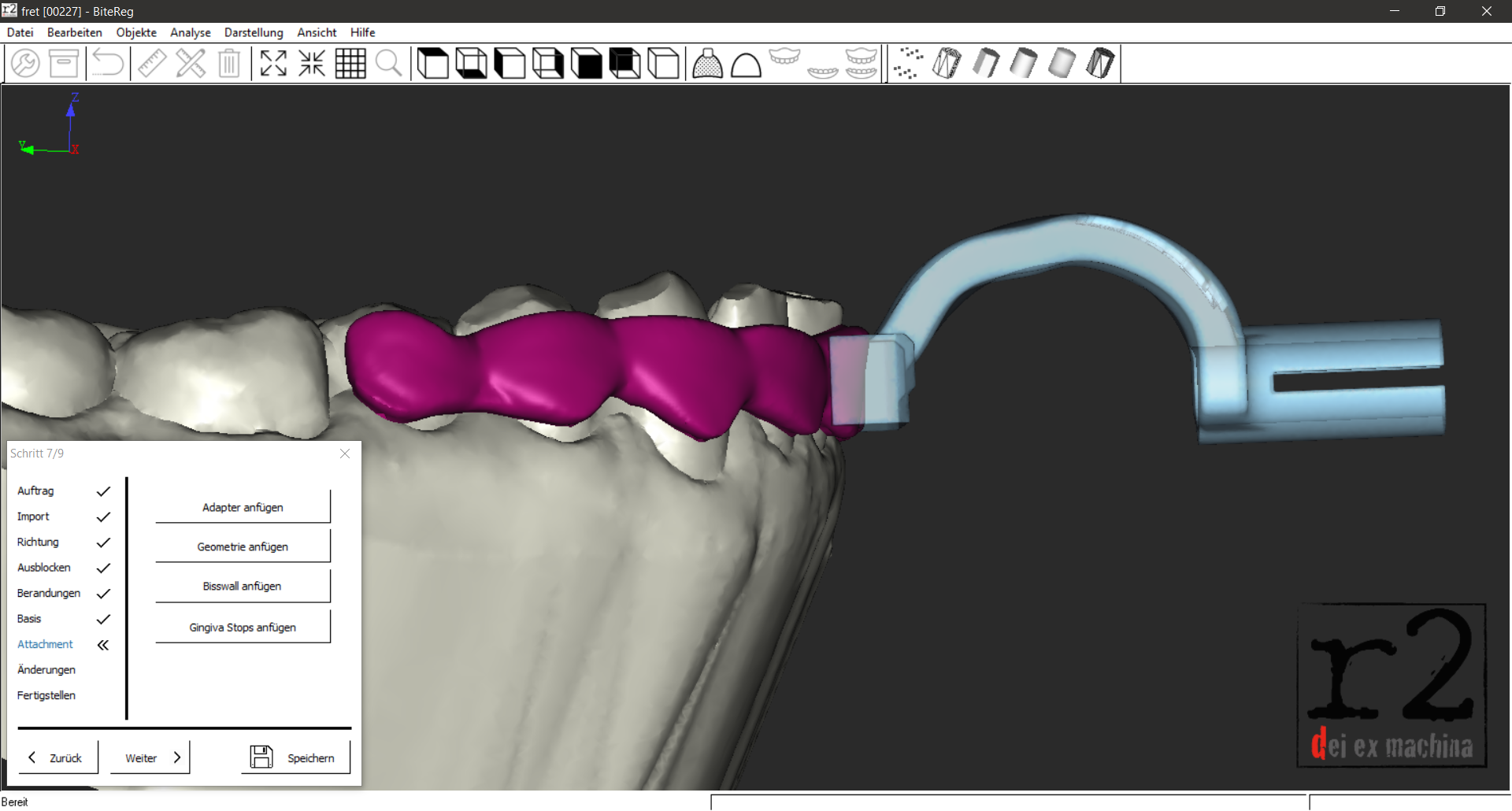

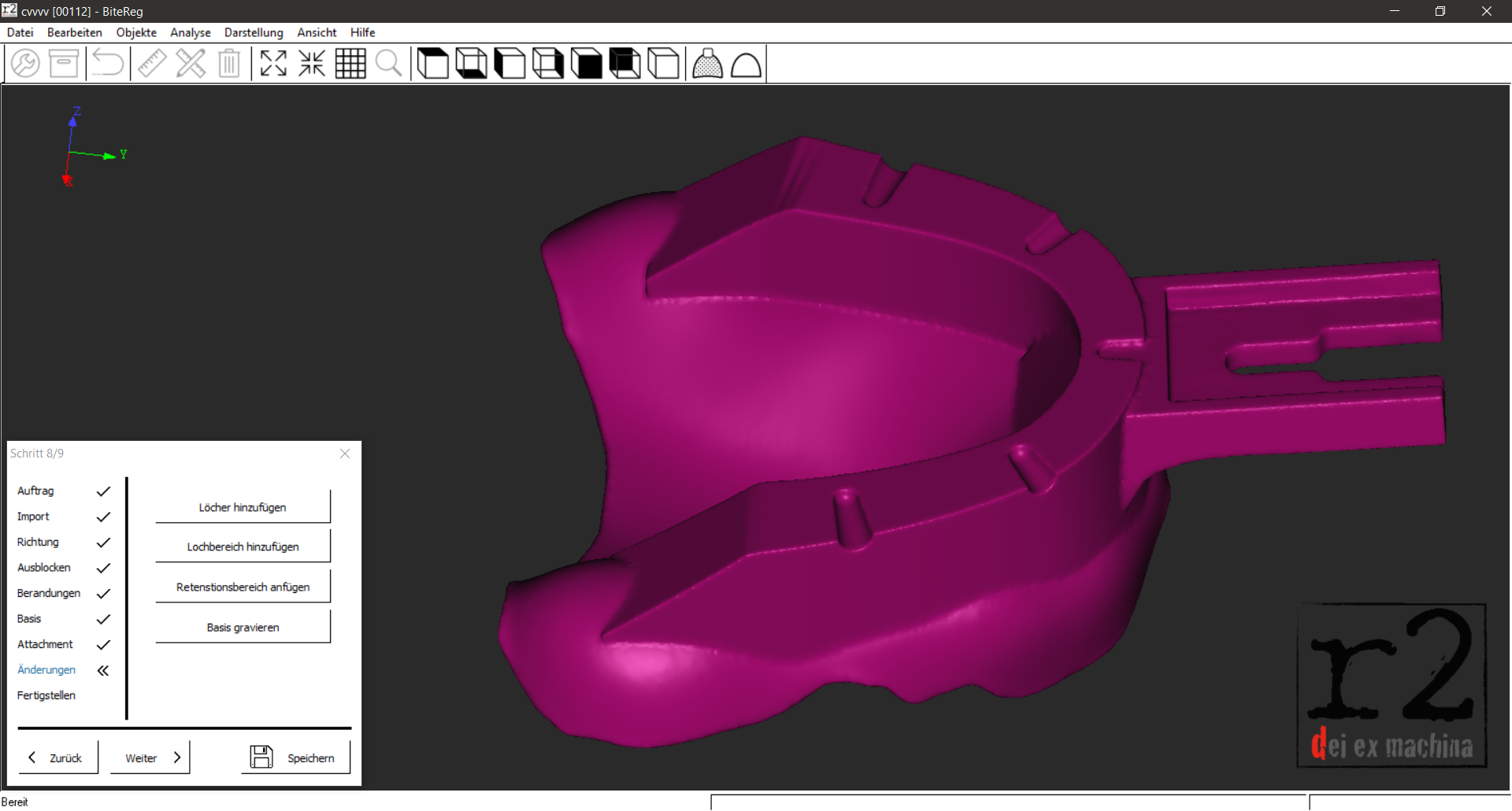

Paraocclusal tray (Figure 9):

- In the insertion direction definable block function for the rail

- Software-integrated holder geometries with automatic positioning parallel to the occlusion plane.

Bite fork (Figures 10 and 11):

- Block function for spongeing the fissures

Figure 17: Easy design for Gothic-arch registration - Integrated adapter geometries with automatic alignment to the occlusion plane (Figure 11).

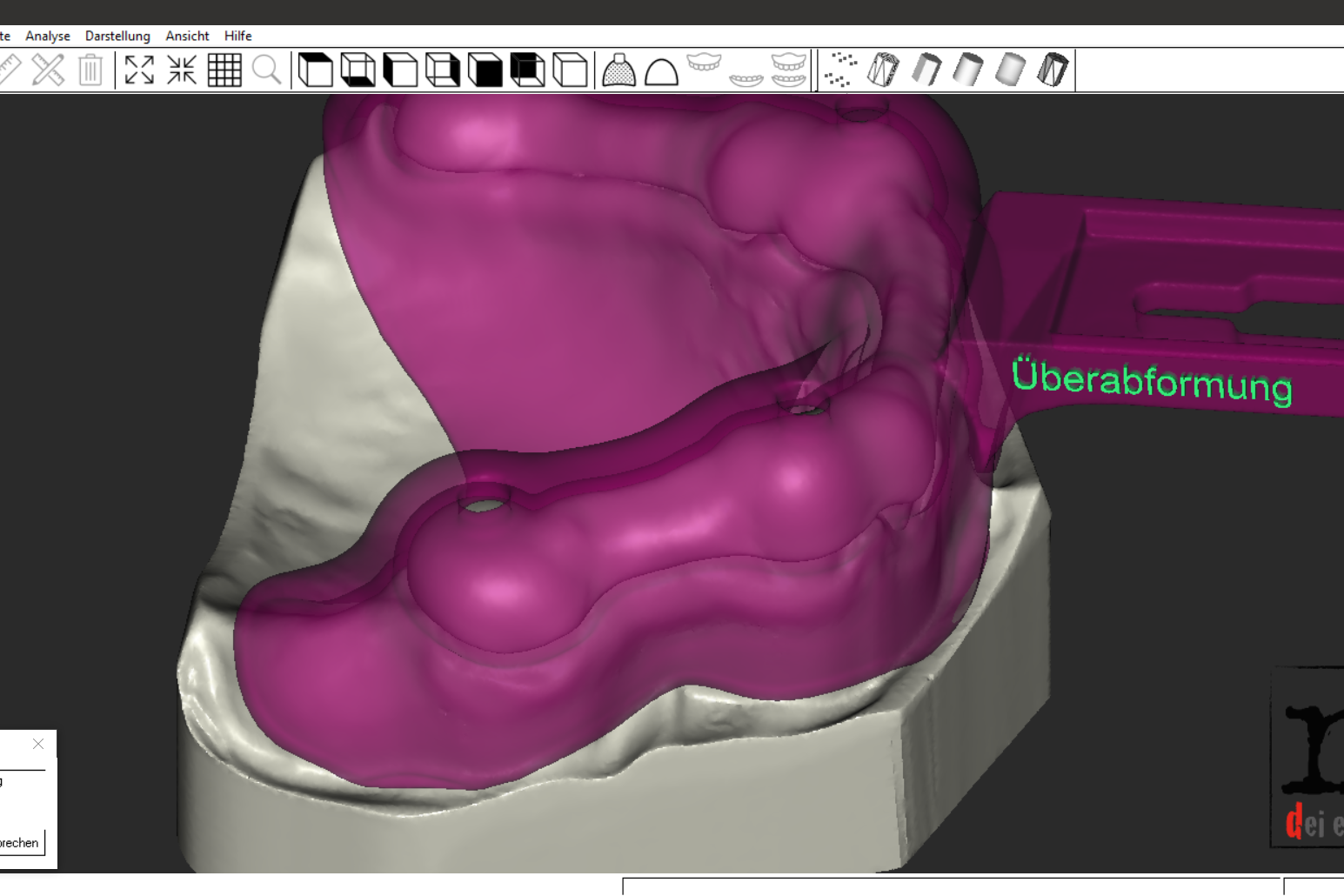

Collective forming (Figure 12):

- Loading Exocad-designed restorations such as webs, telescopes, abutments for the construction of a digital tray for over-forming

- Similarly, the transmission keys constructed in Bite Reg can be re-invited to integrate them into the over-impression (Figure 13)

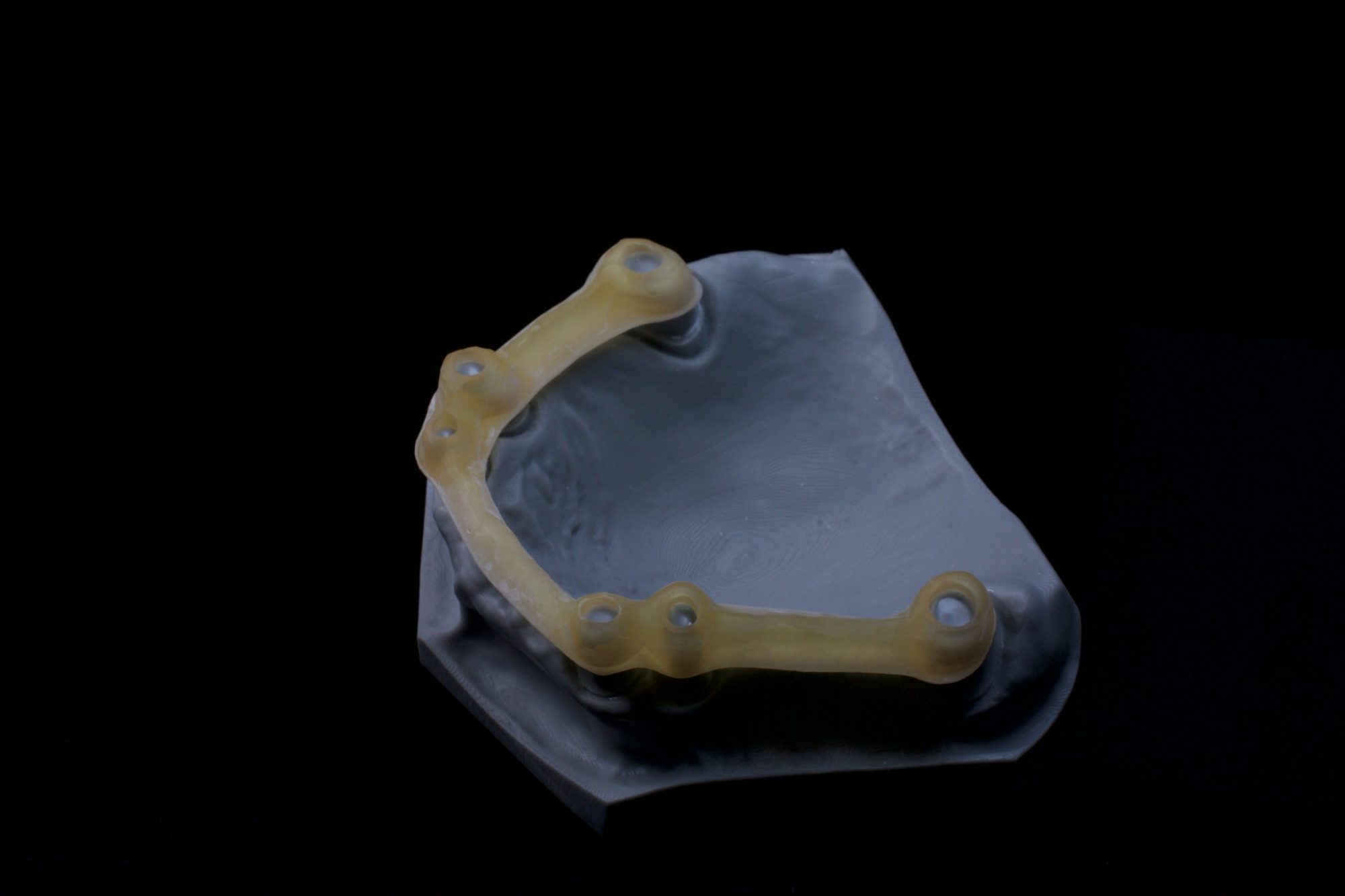

Transmission key (Figure 14):

- Simple hollowing on the gingiva

- Loading of primary telescopes or abutments designed in Exocad (Figure 15)

- Targeted insertion of reinforcements (Figure 16)

Registration (Figure 17)

- Simultaneous construction in the upper and lower jaw

- Fast design of registries thanks to integrated geometries for retaining pin, IPR and AVOSAX registries (Figures 18 and 19)

- Automatic alignment of the writer plate according to occlusion level

- Freely definable distance from the pen to the writer plate as well as free positioning of the pen along the media level (Figure 20)

Summary

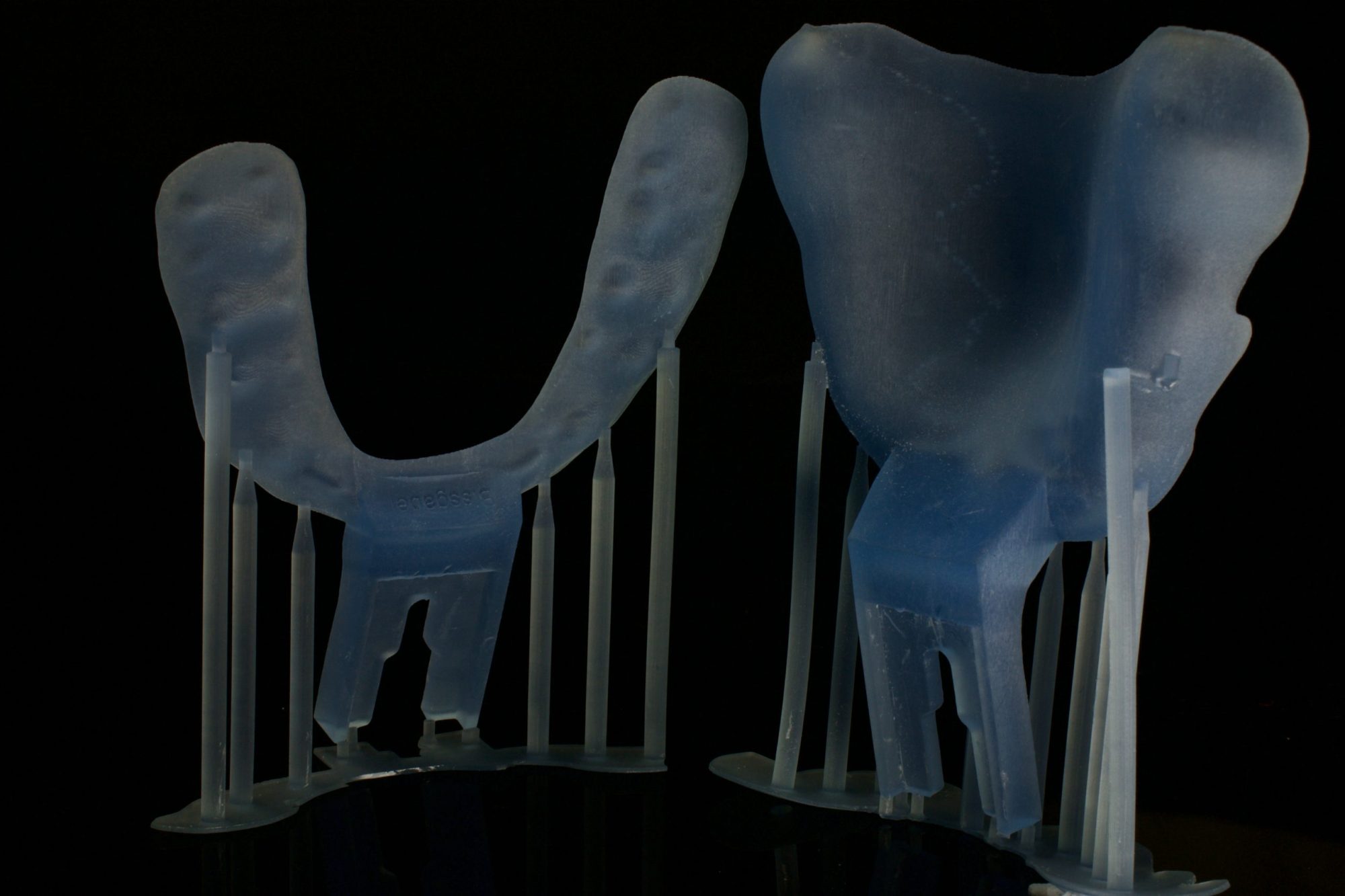

The production of auxiliary parts is an additional application for 3D printing (Figure 21).

Due to its interpretation as an auxiliary part, the remuneration of this service is usually low.

Thus, the construction should be quick and uncomplicated. Coordinated software programs enable the construction directly in the plastics department.

This means that CAD construction workstations and CAD technicians are not occupied. The creation is done with the same staff, who have always been responsible for this.

The simple design is supported by logical wizard steps and targeted software functions tailored to the application area (Figure 22).

Digitisation is not an end in itself. It must always provide meaningful support for the entire work process.

Check out other laboratory articles

- The Godfather of FX teeth – creating teeth for Star Wars, Marvel and Austin Powers

- Orthodontic business appoints leading specialist as CEO

- Beyond the Dental Lab – Jonathan Tasker

- Finding my feet as a dental technician.

Follow Dentistry.co.uk on Instagram to keep up with all the latest dental news and trends.