Stephen Vincent discusses his journey into dental technology, his plans to open a new laboratory and his latest project involving reconstructing the dentition of a human skull.

I have been a dental technician since finishing my five-year apprenticeship in 1985 at a highly regarded dental laboratory in the West End of London.

As soon as I started training, I felt at home and knew that I had found my niche in life. I developed a love and talent for ceramics, and I have specialised in this field throughout my career.

I went on to become lab manager at both private and corporate laboratories working for renowned names in the industry.

In 2005 I started my own laboratory, Allport & Vincent Dental Laboratory, with a business partner. This ran very successfully until it was sold in 2017.

I built a reputation on quality and service and have been working with some of the same clients for 30 years. I firmly believe that every patient deserves my complete attention, and I will always strive to achieve the finest result for them aesthetically and functionally.

I’ve had the same passion for ceramics as I did at 16 years old.

New beginnings

In Spring 2022, I resigned from Allport & Vincent and have taken 12 months off to rest and regroup. During this period, I have decided that I wish to resume my career and will start my new laboratory in May 2023.

I will be concentrating on high-end ceramics with a one-to-one relationship with all my clients, new and old.

It is my opinion that a close and trusting relationship between a dentist and a dental technician can make a real difference to patient outcome. I believe that dentists still value that relationship and like knowing who is on the end of the phone when they call.

Modern dental technology can offer a quite bewildering choice of techniques and restorations. Many dentists are still happy with the humble but extremely successful PFM, while others are embracing digital dentistry with all the CADCAM options that it brings.

I enjoy discussing the possible choices with my clients and am always happy to chat with them and share my wealth of experience. With the belief that traditional still has a place alongside digital, I will use both in harmony to produce the best result I can.

I am a technician best suited to producing quality ceramics at the bench and this is where I’m happiest! I have never sought the spotlight and prefer my work to speak for itself, but I am excited about my skull project and would like to share it with my colleagues in the dental profession.

Project skull

The reconstruction

I have always wanted to reconstruct the dentition of a human skull, but had never previously had the time to devote to such a project. After 43 years, I finally had the opportunity to get the project started.

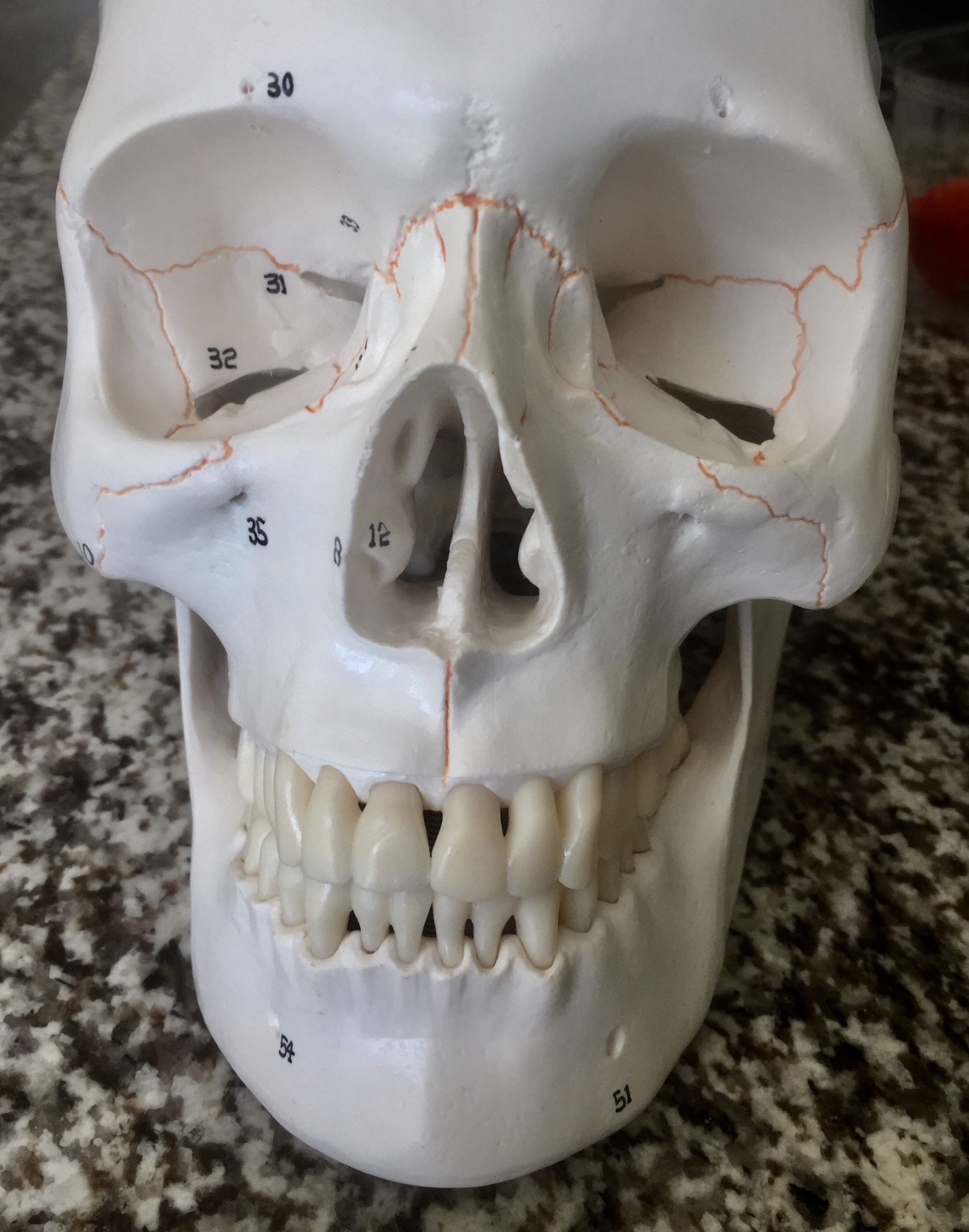

I purchased a replica resin skull from an online supplier in Australia and waited with anticipation for it to make its long journey to the UK.

It came complete with a full set of resin teeth, and I had to prepare each one individually. This was difficult and time consuming as they were fixed to the skull and not removable.

I have a newfound respect for the skill and dexterity of a dentist in preparing a tooth in a live patient. My skull was more forgiving than a patient would be and did not require any anaesthesia!

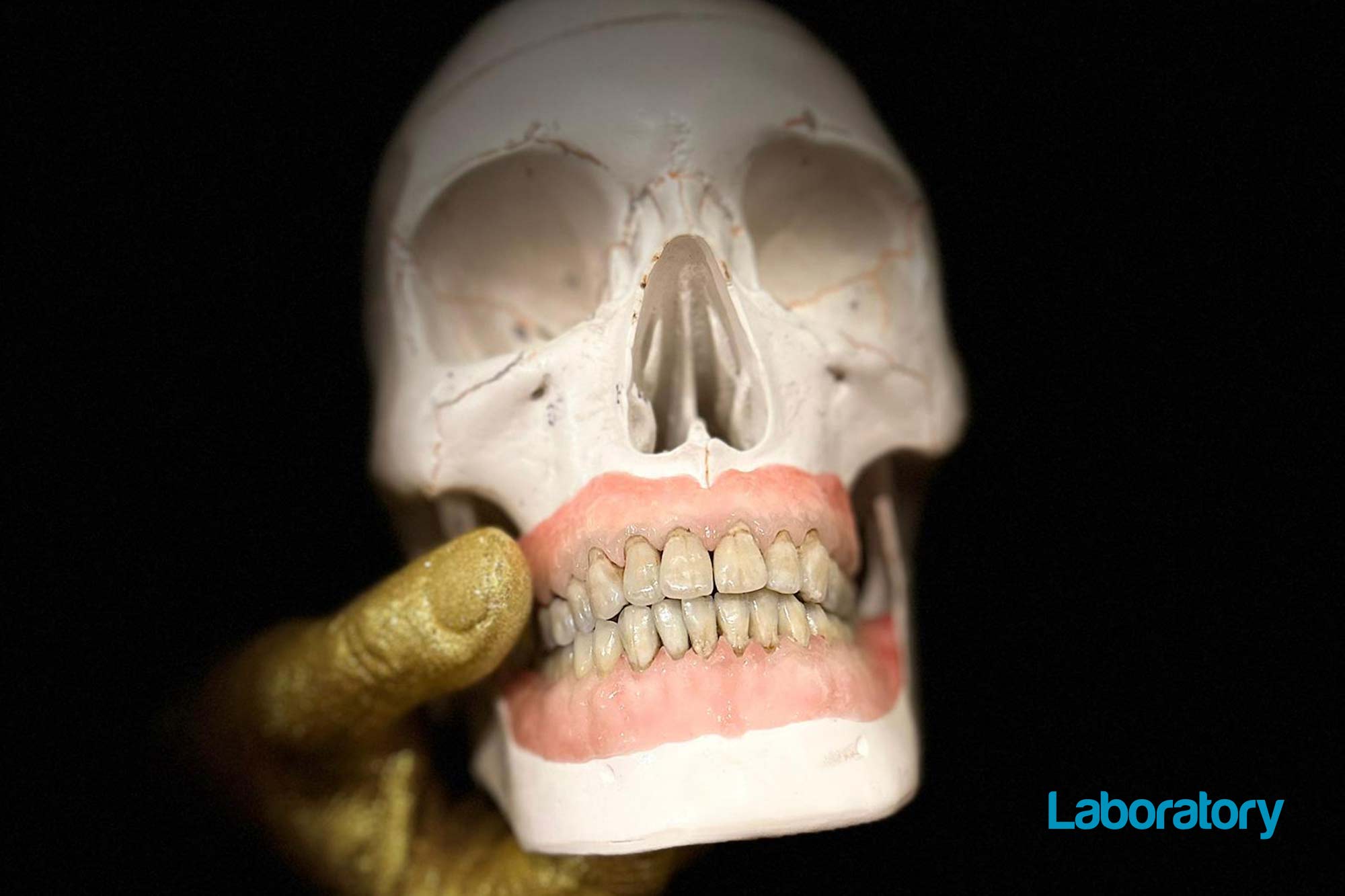

As I would normally in a live case, I started with the upper anteriors and commenced waxing for alloy free copings. These were duly processed in the normal manner and then pressed with a lithium disilicate ingot.

The copings were fitted down onto the preps and layered with porcelain.

Many firings later, I had the beginnings of my reconstruction. The lower anteriors came next, followed by each quadrant of the posteriors in turn.

Several days later, I was happy with the morphology and occlusion.

The finishing touches

I then decided to wax and varnish the gingival areas.

I was now at my favourite stage of the whole reconstruction as I could begin to emphasise the built-in characterisations and depth of colour with stains, ready for a low temperature glazing.

After cooling, I checked everything for fit, finish and quality before I finished each crown with diamond polishing paste. This is to achieve the correct texture and lustre present in natural teeth.

I could now turn my attention to the presentation of the skull. I decided to take an alginate impression of my right hand and proceeded to make a plaster replica. Next I sprayed this gold and mounted the hand, holding the skull on to a wooden plinth.

I ordered a custom made display case and finally my skull was finished.

If I did the restoration a dozen times, each one would be different because that is the nature and beauty of bespoke ceramics.

I loved every minute of the project and now can’t wait to get back to the bench with real cases where I can play my part in making a difference to someone’s life by helping to restore their smile.

Follow Dentistry.co.uk on Instagram to keep up with all the latest dental news and trends.