Manfred Tauber, master dental technician and head of dental education at Renfert Gmbh, and Dr Frank Weber, Renfert’s head of chemistry, carry out a technical and scientific analysis of the polishing of dental hybrid materials.

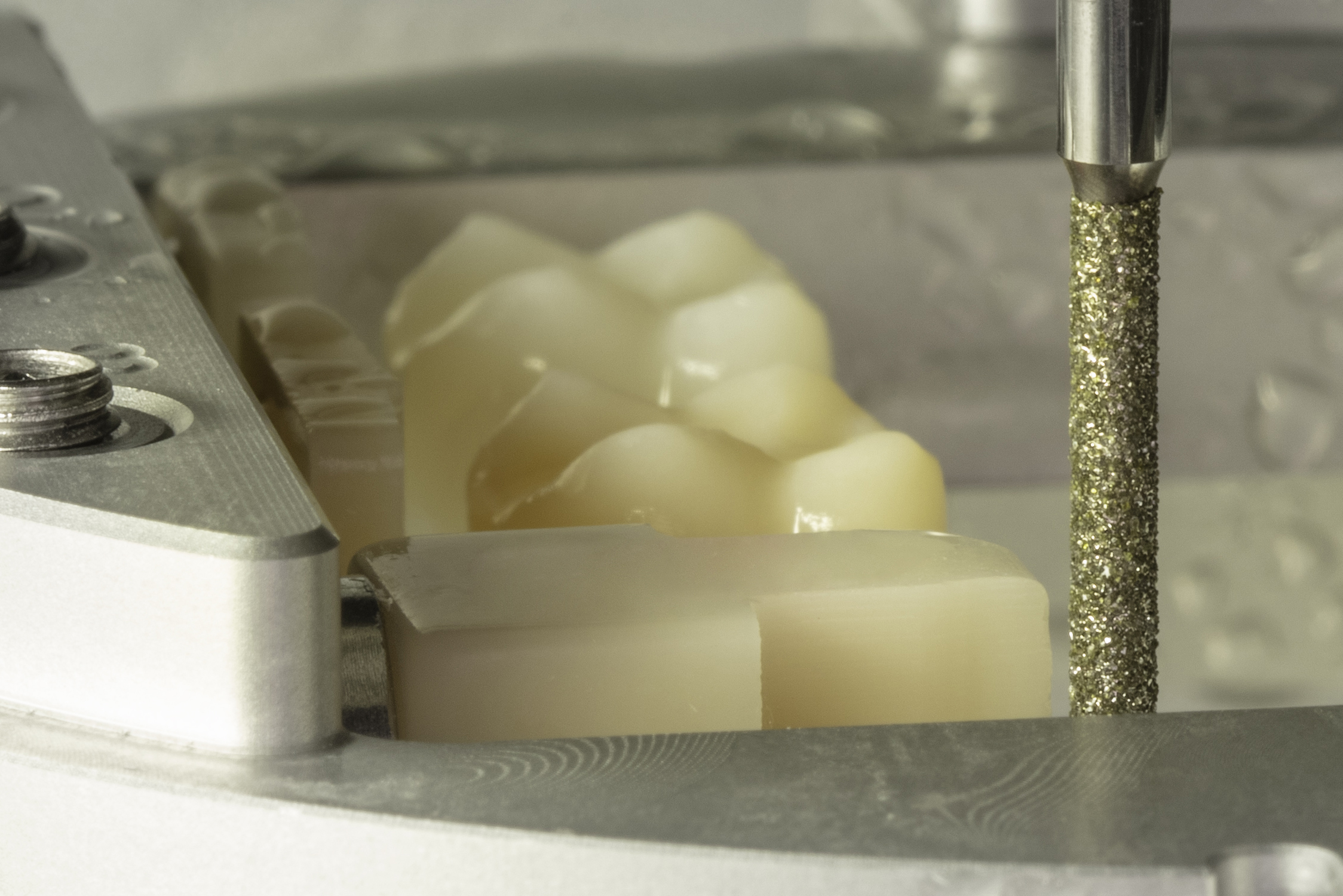

Increasingly, hybrids like CAD/CAM materials and filled veneer composites are used to fabricate indirect restorations. These dental composites unite the posi- tive properties of two very distinct materials.

This combination of ceramics and polymers exhibits a high load-bearing capacity with improved abrasion behavior while at the same time reducing brittleness and allowing easier processing of the restorations.

However, polishing pushes conventional polishing agents to their limits because each of these two materials also has distinct requirements.

Another complicating factor is the uneven material ratio – high ceramic, low composite content – which also varies from supplier to supplier. These are the reasons why much more preparation and polishing work was previously required to achieve a satisfactory gloss level – albeit with limited results.

Renfert Polish hybrid materials comprise a specialised diamond polishing paste which does precise justice to the unique needs of these hybrid materials. The paste is designed to account for both the complex wetting behaviour as well as the different degrees of hardness of the two material proportions.

Why is it so important to polish the surface to a high gloss?

In addition to aesthetic aspects, various authors have demonstrated that the roughness of a surface correlates with the gloss within the high gloss range. On the other hand, the surface roughness has a critical mechanical impact on the antagonist and affects the growth of plaque.

That means that achieving a consistently long-lasting high gloss is thus the most viable indicator of low roughness and, in turn, reflective of high-quality work.

For that reason, Renfert develops, investigates and compares internally as well as through an external authoritative institute the roughness and level of gloss as defined by the gloss units (GU) of the various materials. This is the only way to achieve the optimal outcomes, with consistently smooth surfaces even upon closer inspection.

Lubrication with oils and the application of soft waxes can be used to easily imitate a visual high gloss on the materials, creating a short-term appearance, but that cannot be the objective. Particularly when using veneer composites and modern hybrid materials with composite content, the objective must be to re- duce the plaque affinity as effectively as possible in order to extend the lifetime of the restorations.

The following presents the comparative studies of GU and topographic investigations of the surface roughness measurements of CAD/CAM-produced hybrid materials.

Comparison of various polishing pastes on different hybrid materials

Comparative examination of ‘Renfert Polish hybrid materials’ on different hybrid materials versus the polishing pastes and polishing tools of the competitors.

Description of the investigation and measured data

For this investigation, at least three uniformly shaped test specimens each produced from the respective CAD/CAM block were pre-polished and then polished to high gloss according to the operating instructions under the same conditions.

Subsequently, the test specimens were measured with a Minolta CM2500d operating on the basis of an Ulbricht ball. In particular, the 20° angle required for high-gloss measurement is not only maintained but sharpened to 10° and the measured data determined in gloss units (GU).

In the investigations with Vita Enamic, the highest gloss units (GU) > 120 with the lowest spread of values was achieved with the ‘Renfert Polish hybrid materials’ polishing paste developed by Renfert.

This not only shows that excellent results can be achieved, but also that they are more reproducible than with comparator polishing sets or polishing pastes.

Topographic investigation of polished material surfaces

Three surface measurements respectively were conducted for each of the 7 hy- brid materials on a non-polished sample and a sample polished to a high gloss with ‘Renfert Polish hybrid materials’.

As examples, the measured data of three hybrid materials with very disparate surface structures are presented. The fol- lowing examples show a measurement before and after polishing. The investigations were carried out using a Microprof with a CFM confocal microscopic sensor and a 50x objective at a measuring field size of 375 x 278 μm2. All measurements were used to analyse the surface texture according to DIN EN ISO 25178.

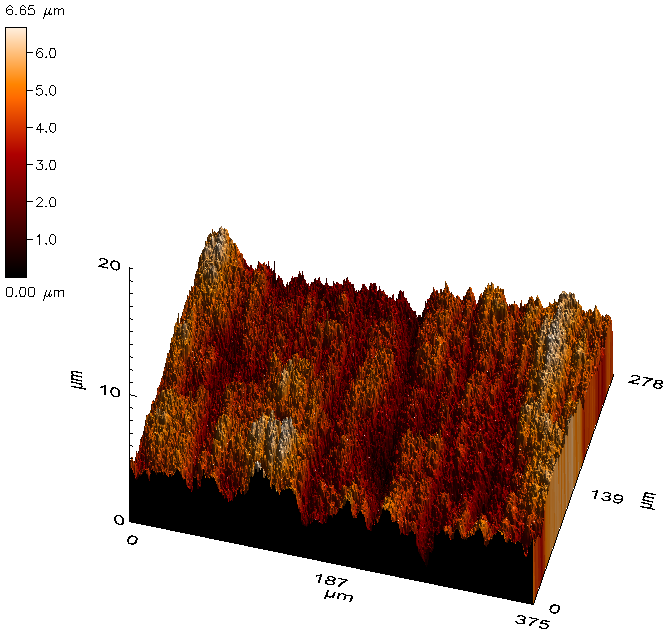

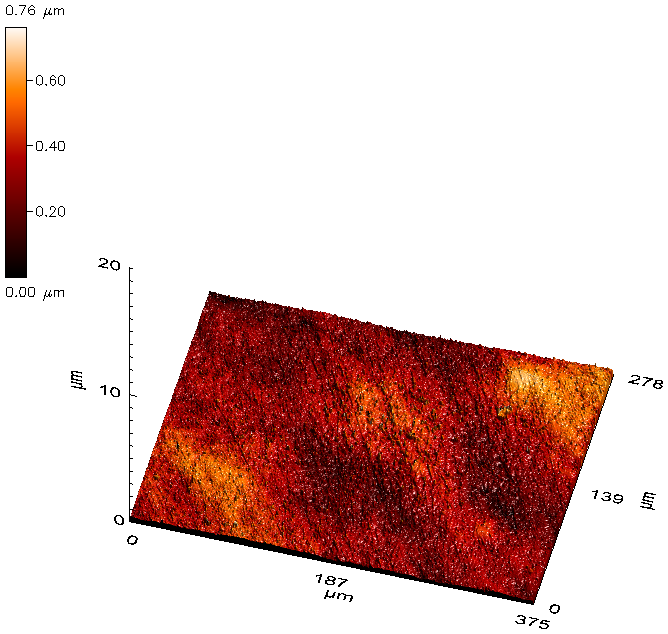

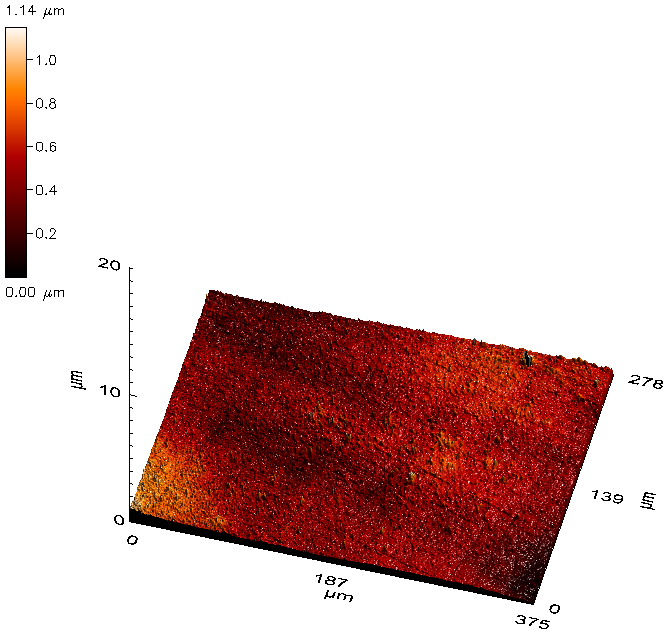

Results of Vita Enamic before and after polishing

A long list of parameters were evaluated to investigate the surface roughness. Standard deviation (SD) is mostly commonly used measurand to describe error from the mean.

Even more striking is the three-dimensional plotting of the measurement results. Please note the markedly magnified scale (colour) representing the polished case. The scaling of the heights/depths (z-axis) is the same, thereby ensuring a direct comparison of before and after polishing. The general processing tracks (see 3D test view 1), could be reduced to a minimum by polishing (see 3D test view 2).

Suitability for other hybrid materials

Other widely used materials were polished and measured to establish whether the results can also be transferred to other hybrid materials. Only two representatives are shown here as examples.

Overall, it was shown that a sustained high gloss with a very low degree of roughness can be easily achieved efficiently and with little initial training on the part of the user.

In conclusion, the ‘Renfert Polish hybrid materials’ closes the gap between polishing pastes for purely ceramic materials ‘Renfert Polish Lisi2’, ‘Renfert Polish Zro2’, ‘Renfert Polish all-in-one’ as well as ‘Opal L’ for pure resins.

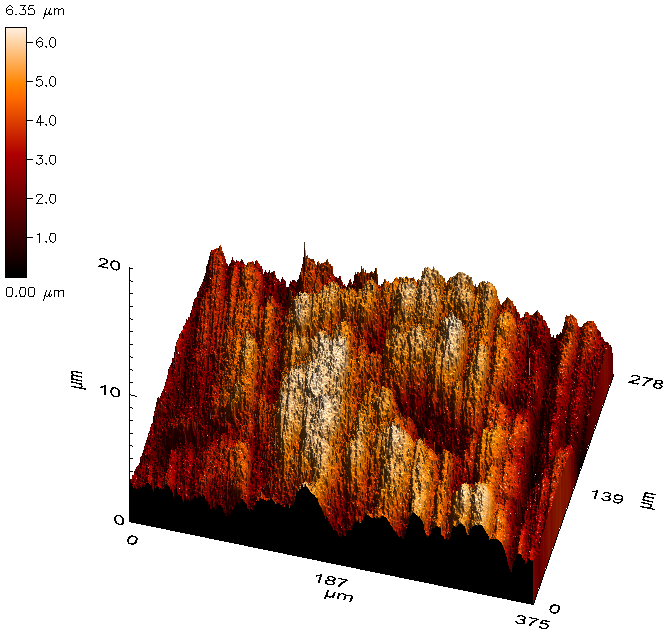

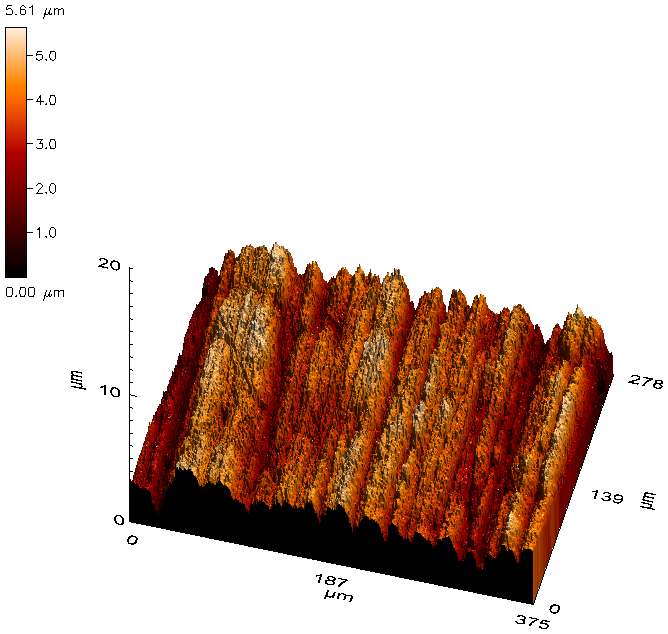

Results on GC Cerasmart

For direct comparison, refer to the SD values.

And in turn, even more striking is the three-dimensional plotting of the results/measured data. The scaling of the heights/depths (z-axis) is the same, thereby ensuring a direct comparison of before and after polishing. Polishing reduced the processing tracks and one marked defect (see 3D test view 3) to a minimum (see 3D test view 4).

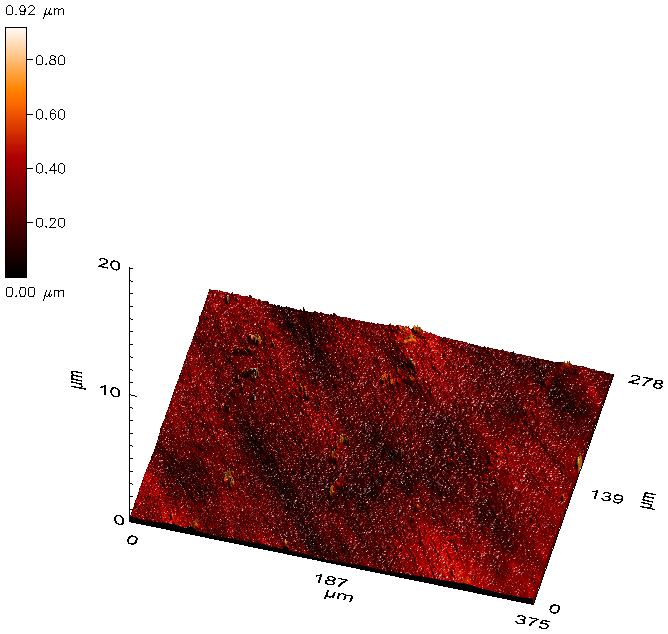

Results on 3M Lava Ultimate before and after polishing

For direct comparison, refer to the SD values.

Here as well, note the three-dimensional plotting of the results/measured data. With same scaling of heights/depths (z-axis) and therefore directly comparable. Polishing reduced the parallel processing tracks (see 3D test view 5) to a minimum (see 3D test view 6).

For further information on Renfert Polish hybrid materials visit: renfert.com/renfertpolish.

Email [email protected] for references.