Mauro Fazioni and Andrea Lombardo discuss the importance of making implants with toothlike restoration materials and how you can do this.

Mauro Fazioni and Andrea Lombardo discuss the importance of making implants with toothlike restoration materials and how you can do this.

Implant-supported restorations are firmly anchored into the bone.

That is why it is important for implants to be made with restoration materials that are able to absorb chewing forces. This is to minimise the risk of overstressing the antagonist, the restoration and the peri-implant bone.

The natural hard tooth substance is a balanced hybrid made of resistant enamel and equally elastic dentine.

Dentist Mauro Fazioni and dental technician Andrea Lombardo explain how this natural recipe for success can be transferred to implant-supported crown restorations.

In the following case, the authors used two different CAD/CAM materials for the superstructures. The reason for this was to intelligently combine elasticity and wear resistance.

These materials were the hybrid ceramic Vita Enamic IS and the feldspar ceramic Vitablocs Triluxe forte. Both of them are from Vita Zahnfabrik, Bad Säckingen, Germany.

Patient case and material selection

A 32-year-old patient presented at the practice with two persistent primary teeth that were no longer worth preserving. This is because they had failed to attach to tooth LR5 and LL5.

After a thorough consultation, the patient decided to have the deciduous teeth extracted and undergo an implant restoration.

In order to reproduce the elastic dentine, the abutments were scheduled to be fabricated individually from the hybrid ceramic Vita Enamic IS, due to its dentine-like elasticity.

The pre-integrated interface allowed for efficient CAD/CAM-supported fabrication and guaranteed a precise fit to the titanium base.

Reproducing the play of colours and light, as well as the functional properties of the mineral enamel, was to be achieved using crowns made of the polychrome feldspar ceramic Vitablocs Triluxe forte.

Surgery and CAD design

The two deciduous teeth were extracted under local anesthesia.

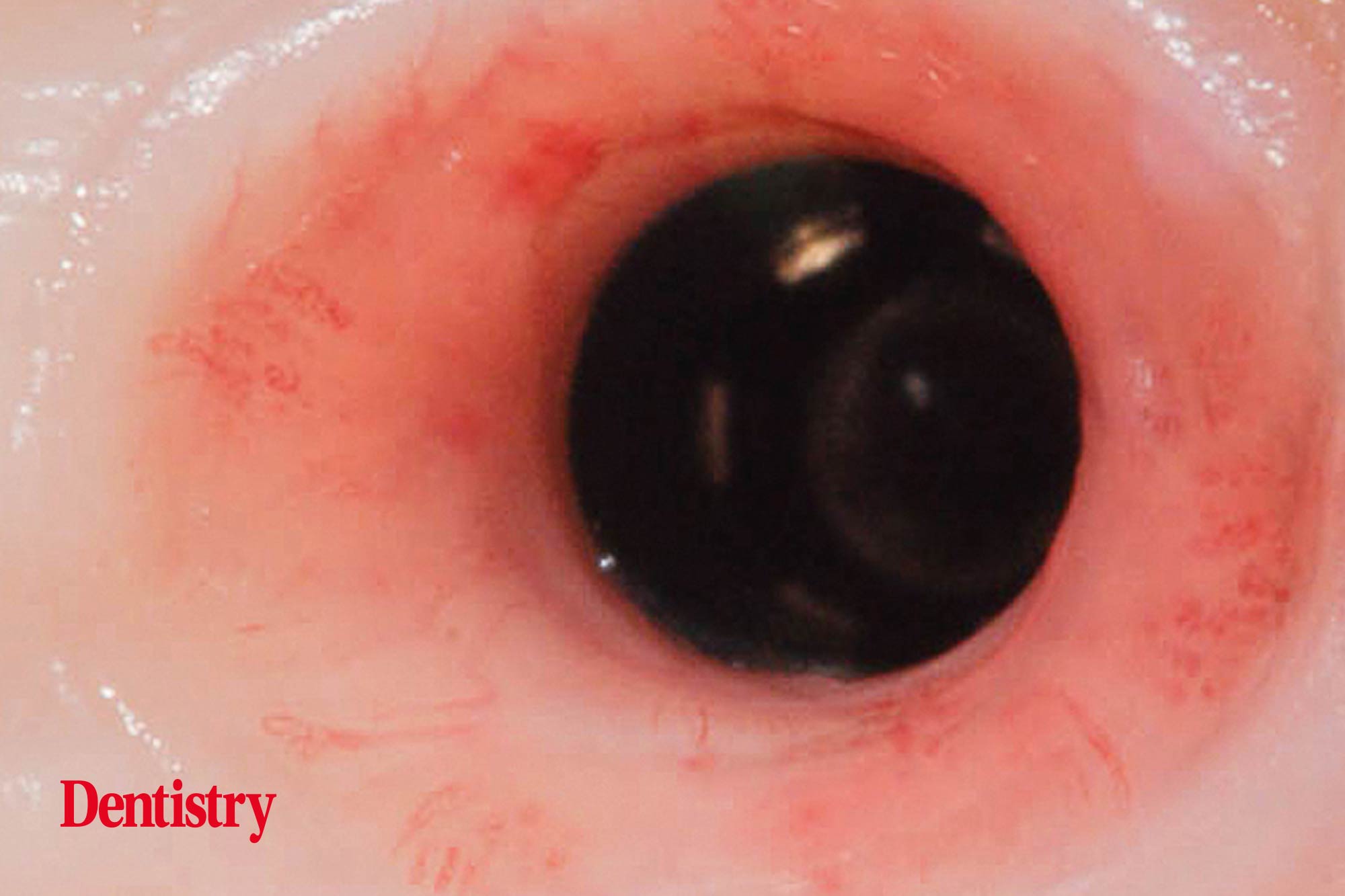

After a healing period of three months, two Ankylos implants were inserted at tooth LL5 and LR5.

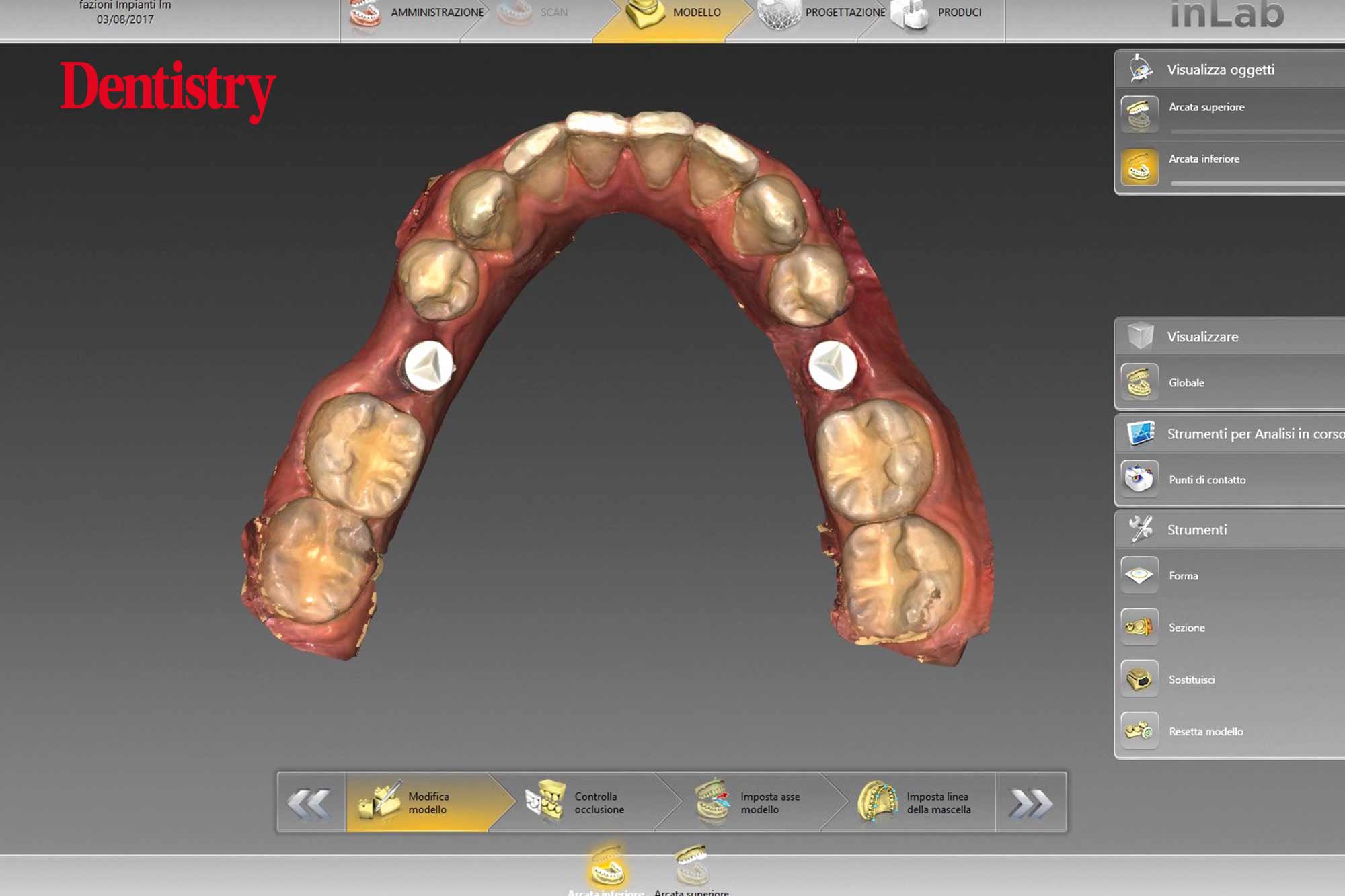

After healing and exposure of the implants, scanbodies were placed. The situation was then digitalised using the Omnicam.

Using the Inlab software (all from Dentsply Sirona, Bensheim, Germany), abutments and crowns could now be designed in line with the natural tooth structure.

In addition, they could then be produced with the CAD/CAM materials Vita Enamic IS and Vitablocs Triluxe forte.

The coronal margins were not created subgingivally. This was in order to ensure a simple and clean adhesive cementation of the crowns under the rubber dam.

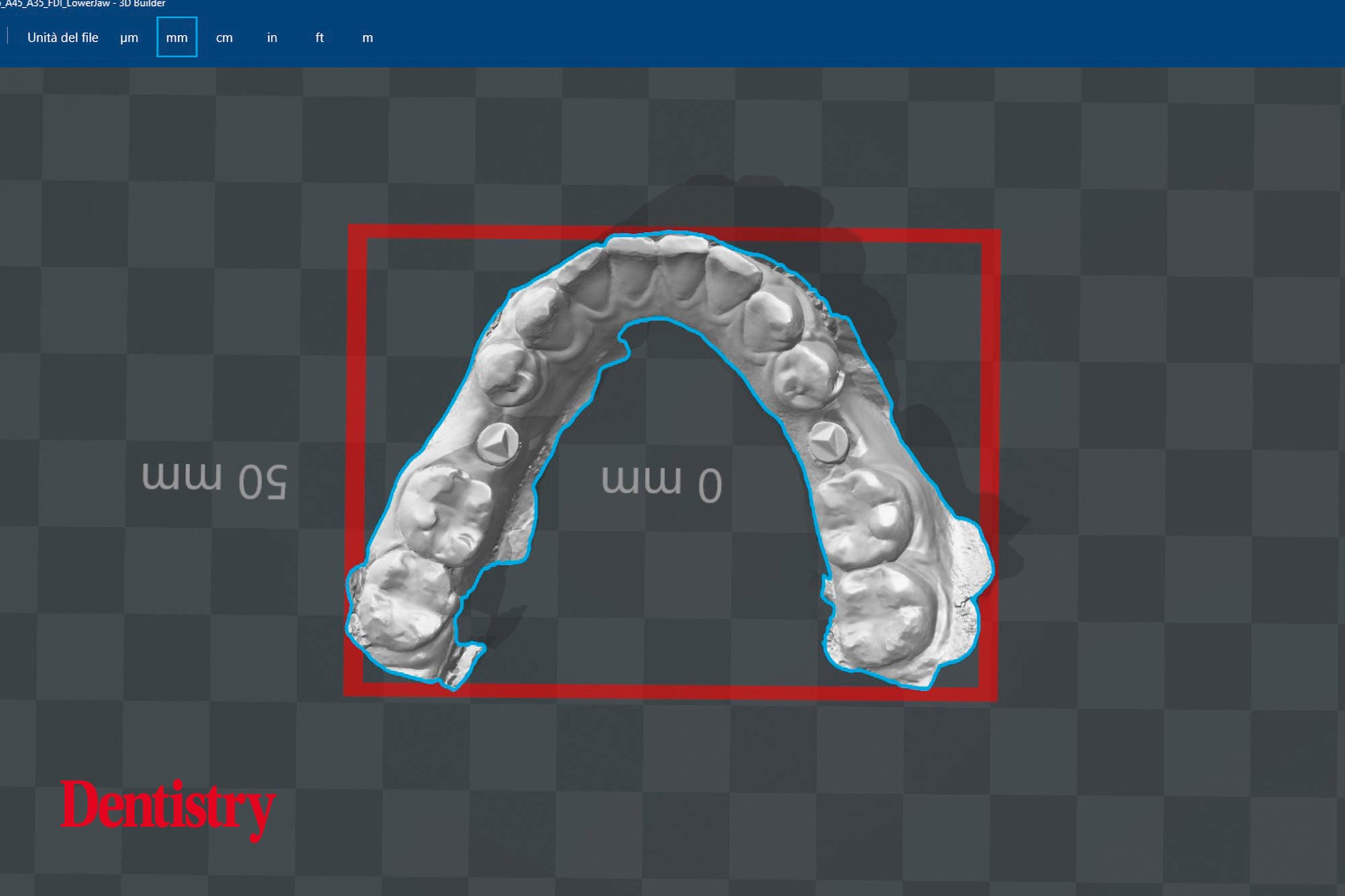

Additive manufacturing was used to produce a model with integrated implant analogues to check the fit (XFAB, DWS, Vicenza, Italy).

CAM production of implant-retained dentures

After CAM production, manual finishing and a check of the fitting, the hybrid ceramic abutments were adhesively bonded to the titanium base.

For this purpose, the adhesive surfaces of the abutment were etched with hydrofluoric acid (5%) for 60 seconds. They were then silanised.

The adhesive surfaces of the titanium bases were blasted with 50μm aluminum oxide at 1.5bar, and a metal primer was applied.

The adhesive bonding was done using an opaque composite cement.

After hardening and removal of the excess, the final hardening was completed under glycerine gel. This was in order to prevent an oxygen inhibition layer from forming.

Finally, the fissures of the CAM-fabricated and manually prepared feldspar ceramic crowns were characterised with the ceramic stains Vita Akzent Plus Effect Stains 06 (russet).

They were then glazed with glaze paste.

Try-in, final result and conclusion

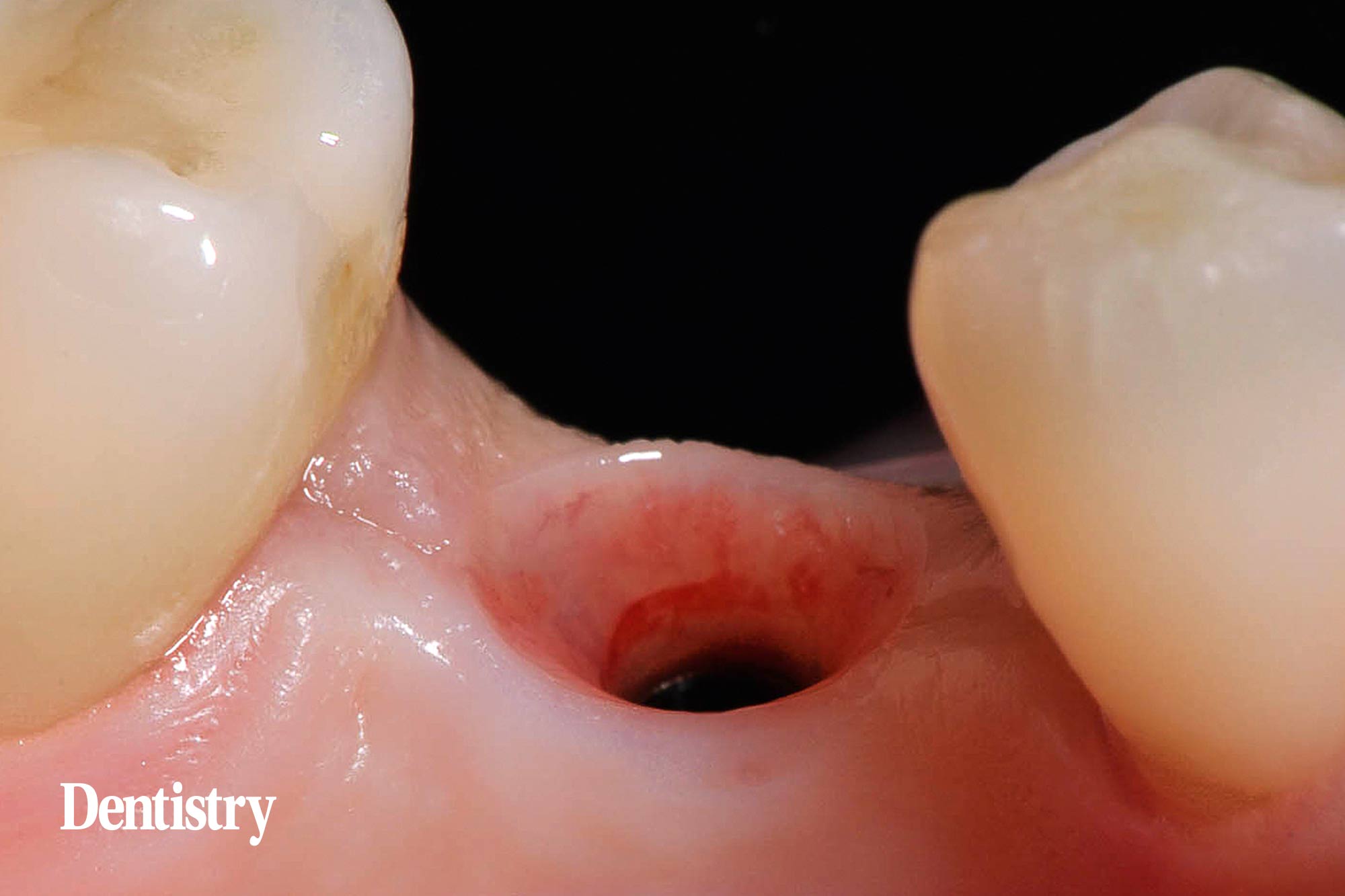

The clinical try-in showed perfectly healthy soft tissue conditions and a smooth fit of the restorations after the removal of the gingiva former, and were ready to be prepared for final seating.

To achieve this, the adhesive surfaces of the abutments and crowns were etched extraorally with hydrofluoric acid and silanised.

After the abutments were screwed in, a rubber dam was placed. In addition, the crown was then adhesively bonded to the abutment intraorally.

The full adhesive bond between the hybrid ceramic abutment and the feldspar ceramic crown resulted in a biomimetic unit that reproduced the tooth structure very well, both aesthetically and functionally.

As a result of the chewing-force absorbing properties of the hybrid ceramic, good long-term durability is expected for this restoration.

The integrated colour gradient in the feldspar ceramic crowns give this monolithic restoration an aesthetically convincing look.

This article was initially published in CAD/CAM International Magazine of Digital Dentistry, Italian edition 02/2019.

Follow Dentistry.co.uk on Instagram to keep up with all the latest dental news and trends.