Guy Hiscott visits Dürr Dental’s Stuttgart headquarters for the real story on how the legacy of its past is shaping the innovation of its future.

History looms large at Dürr Dental.

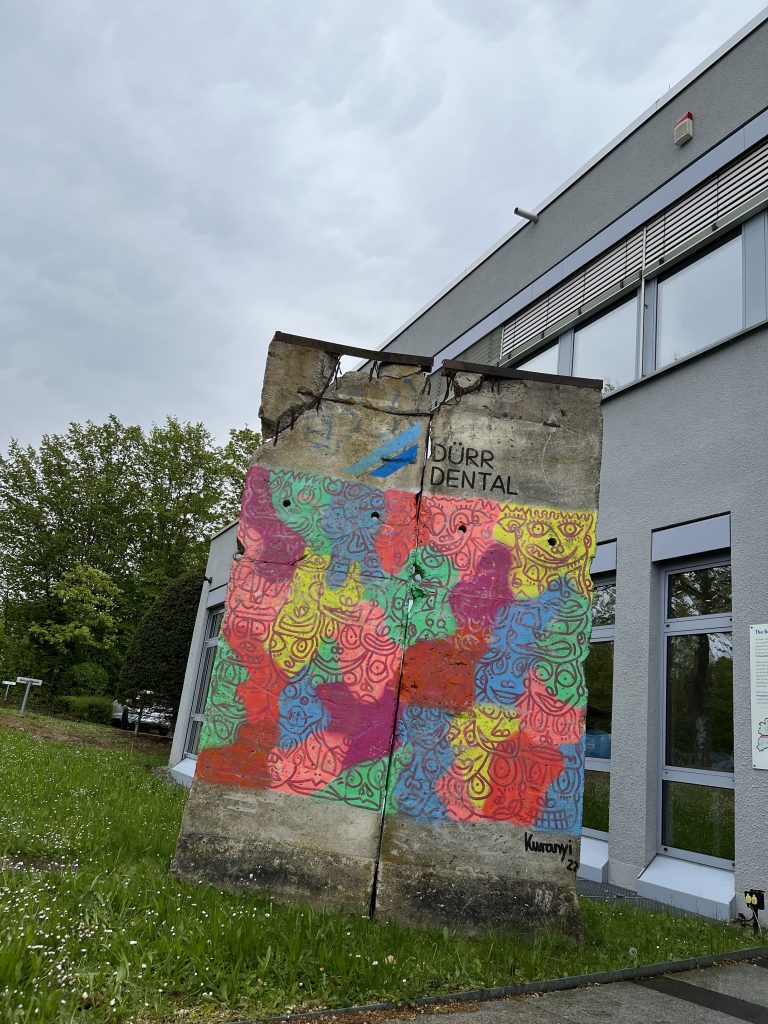

And understandably so: the company has been helping dentists treat patients for more than 80 years. But even so, the past is a constant companion at Dürr Dental’s offices, whether it’s mural-sized photographs of yesteryear or a fragment of the Berlin Wall, decorated and turned into defiant artwork outside its Bietigheim-Bissingen headquarters.

Don’t be fooled. If this gives the impression that Dürr Dental is living in the past, it couldn’t be further from the truth.

Indeed, even calling it ‘history’ feels like a disservice to a company that today manufactures and supplies some of the most advanced dental technology on the market to more than 170 countries across the world.

Heritage. Tradition. These are perhaps better terms. And perhaps ironically, nowhere is that heritage more evident than at Dürr Optronik, a production subsidiary of Dürr Dental, where nearly all of its state-of-the-art digital imaging devices are assembled. The factory nestles in the wooded hills on the fringes of the Schwarzwald, Germany’s famous Black Forest.

Dürr is more than dental: one of its biggest subsidiaries is Dürr NDT, which deploys its imaging technology on ‘non-destructive testing’ in sectors as varied as defence, maritime research and aerospace engineering.

There’s a large chance that its air extraction technology is helping keep your local petrol station forecourt significantly less flammable even as you read this. And its compressors – at least, a version of them – can be found in the majority of McDonald’s European restaurants, helping carbonate the soft drinks.

Before the factory, there was a barn, where the Dürr brothers first plied their trade. The Schwarzwald is rich with stories, and the Dürr Dental team is happy to play its part, sharing knowledge and anecdotes freely as I tour the facility with a band of engineers and dental dealers from the UK.

Legend has it that the deer’s head gazing out impassively over the conference room on the factory’s top floor once graced a wall in that original barn. Once, it may have watched brothers Karl and Wilhelm Dürr as they worked, repairing dental handpieces in the wake of World War II.

Today, it observes the fleets of engineers, salespeople and other visitors passing through to hear about Dürr Dental’s latest digital innovations. The modern factory is a far cry from the company’s humble beginnings. On the floors below, workers assemble everything from scanners to CBCT units effectively from scratch, even down to printing the circuit boards themselves. (This, of course, is not a new development – Dürr Optronik has been doing so since 1982.)

The legend of Dürr

The factory nestles in the wooded hills on the fringes of the Schwarzvald, Germany’s famous Black Forest. Before the factory, there was a barn, where the Dürr brothers first plied their trade. The Schwarzwald is rich with stories, and the Dürr team is happy to play its part, sharing knowledge and anecdotes freely as I tour the facility with a band of engineers and dental dealers from the UK.

Legend has it that the deer’s head gazing out impassively over the conference room on the factory’s top floor once graced a wall in that original barn. Once, it may have watched brothers Karl and Wilhelm Dürr as they worked, repairing dental handpieces in the wake of World War II.

Today, it observes the fleets of engineers, salespeople and other visitors passing through to hear about Dürr Dental’s latest digital innovations.

The modern factory is a far cry from the company’s humble beginnings. On the floors below, workers assemble everything from scanners to CBCT units effectively from scratch, even down to printing the circuit boards themselves. (This, of course, is not a new development – Dürr has been doing so since 1982.)

Balancing past and future

At every turn, the company practically resonates with the care it takes to strike a balance between past and its future. It’s understandable: the business is still family owned, with CEO Martin Dürrstein the third generation to hold the reins. Over the last eight decades, the company has grown to employ more than 1,300 people, with a turnover of more than 360m. This is not something that happens by clinging to the old ways.

Take Dürr Dental’s dedication to flexible working. This is such a big part of the company’s remit that at the Dürr Optronik site, it has lead to a majority female workforce on the production lines, recruited mostly from the local area.

This same team personally signs off – and sign – each piece of equipment built before it leaves the factory. It’s a touch that feels delightfully anachronistic in a world of mass automation, yet it’s one that speaks perfectly to the company’s approach.

Detail focus

Make no mistake: these are modern, high-tech manufacturing sites. They’re powered by Kanban processes, RFID chips and complex machinery – but its fiercely detail-focused engineers are just as important to the mix.

It’s fortunate that Dürr Dental cares about detail, because there are many to be shared as we tour the facilities. There are 180 stages to building this component; 80 steps to that. Each new workstation we visit is a portal to new designs and processes.

We learn that CBCT units need optical cable to carry the imaging information to the processor because copper wiring can’t handle that much information. Then we find out how long it takes for the ball bearings in the motorised arm to even out the lubricant and move smoothly. Finally we learn about the different ways to mount components on circuit boards (‘through the hole’ and ‘surface mount’, in case you’re interested).

The details are endless, yet they are all fascinating, and it’s obvious that we are barely scratching the surface. It doesn’t hurt that each fresh fact is delivered with the same blend of pride and passion, and the cast-iron certainty of its importance.

Made in Germany

If there is one fact that the team is adamant that we retain over all others, it’s that to ensure maximum quality standards, Dürr Dental produces almost exclusively in Germany.

‘Before they understand, people always think that we just ship in parts from abroad, put our name on them and send them out,’ confides overseer Daniel Theobald, as we walk past an engineer in the head office, carefully assembling a Dürr Dental power tower.

‘But we don’t deal in other people’s parts – we make it all, and we make it all here.’

The full truth of this becomes even more apparent as we pass an area where yet more equipment is being made. This time, it’s many of the tools needed to manufacture the products themselves.

‘I can buy a bench if I need one,’ Daniel continues. ‘But if I build the bench that I need, I know I’m getting one that’s perfect.’

High-tech but human

The manufacturing floors themselves hum with calm, focused activity. Before seeing the facility for myself I expected noisy, automated factories, but there is none of that. Instead, there are carefully ordered rows of craftspeople, working in unison.

Awards and accolades hang everywhere, testament to the quality of the work that these high-tech but still very human places of work put out.

Because that human touch too is a theme. We watch as a compressor is built by hand in front of our eyes. The process pauses at every step of the way for testing. It’s just standard practice, Daniel tells us with pride: ‘Everything from this factory is not just 100% hand made. It’s 100% tested before it goes out, too.’

There is a reason that German engineering carries a premium, of course. There’s a palpable sense that the Dürr Dental team is not just shouldering its own responsibility but is delighted about doing so.

‘We have about 120 people working here,’ explains CEO Peter Dürrstein of the Dürr Optronik facility in Gechingen. ‘And we are totally focused on production. We don’t have a sales department; we don’t have R&D, we don’t even have administration – this is all done in Bietigheim. What are we producing here? It’s in the name – Optronik. Optics and electronics, so our imaging products, camera sensors, scanners, you name it.

‘They’re nearly all made here, start to finish. Made in Germany: that’s the story.’

Telling stories

It’s certainly the headline, but it’s not the only story. While dentistry is where the story began, the Dürr Dental Group’s work today extends far beyond healthcare.

Its imaging expertise comes in high demand in the non-destructive testing (NDT) market, for example. Dürr’s imaging technology can be found doing everything from verifying the integrity of welding on pipelines to putting telecommunication satellites into orbit. Word on the street is that the Ministry of Defence is a key customer too – though the grapevine doesn’t extend to what’s being tested.

NDT is a bigger market than dental, it turns out. And one that – brace yourself – asks for even higher imaging standards.

But it doesn’t end there. As another example, Dürr’s compressor and ventilation technologies being used everywhere from petrol stations to pubs. For a name that looms so large in dentistry, it’s a genuine surprise (to me at least) to find out how much further its influence spreads.

Then again, after seeing where this equipment is made, it’s perhaps not so surprising.

‘Love your neighbour as you would love yourself’

Peter ends our time at his factory by sharing the company’s wider philosophy – which predates even the Dürr brothers and their old barn.

‘Our approach comes back to words from the Bible – love your neighbour as you would love yourself.

‘This is our approach at Dürr Dental too. Treat others right: not just your customers but your employees, your suppliers, the environment. Without our suppliers, we couldn’t operate. Without our customers, we would have no business.

‘Trying to do better by everyone is just good business – and that’s what drives us.’

Between these philosophies and its processes, it’s no leap to picture Dürr Dental celebrating more milestones in another 80 years’ time. The stories it will have to tell then are anyone’s guess – but something tells me there will still be plenty to say.

For more information about Dürr’s dental offering, visit www.duerrdental.com.

This article is sponsored by Dürr.